Predictive resupply analytics -

Predictive analytics and similar AI-based solutions have been introduced into SCM to boost supply chain analytics, generate better forecasts for demand, optimize inventory levels, and reduce costs by reducing waste.

What is predictive analytics? How can predictive analytics help your supply chain? And what are some challenges you might face when implementing forecasting solutions? This article will answer all these questions. Companies working along the supply chain are already using various data analytics in their operations.

Most of the analytics currently in use are descriptive in nature. Descriptive analytics is a set of tools for summarizing data and spotting trends. This type of analysis does not predict the future but instead describes what has happened in the past based on historical facts, figures, statistics, and so forth.

Diagnostic analytics intends to give insights into why something happened. Every analytic process begins with the collection of data.

Data can come from various sources, including sales and purchase forms, invoices, delivery notes, CMRs, customs documents, etc. Supply chains are complex and therefore produce lots of data.

The challenge is to process this data and use business intelligence analytics to understand what happened, why it happened, and make the best business decisions about the future. Predictive analytics takes the data another step further, answering questions about the future - what will happen?

The most powerful and impressive data science analytics is about gaining foresight and an intelligent action plan with prescriptive analytics. Cognitive analytics aims to replicate human thought processes and behavior, and they can be used to address challenging, complicated questions.

These analyses are capable of taking into account factors such as context when interpreting findings. To perform this, cognitive analytics uses artificial intelligence, particularly machine learning and deep learning, to become more intelligent over time.

Cognitive technologies can comprehend, reason, learn, and interact like a person, with far greater efficiency and speed than humans can.

This may considerably cut down on the amount of labor needed by staff to generate these reports and analyses and allow people outside the data science team access to the results. Predictive analytics is one of the most popular branches of statistics within the data analytics field.

The idea behind predictive modeling is to make use of past data to predict future events or behaviors, which companies can use for the better supply chain management. The supply chain is also important in other industries, e.

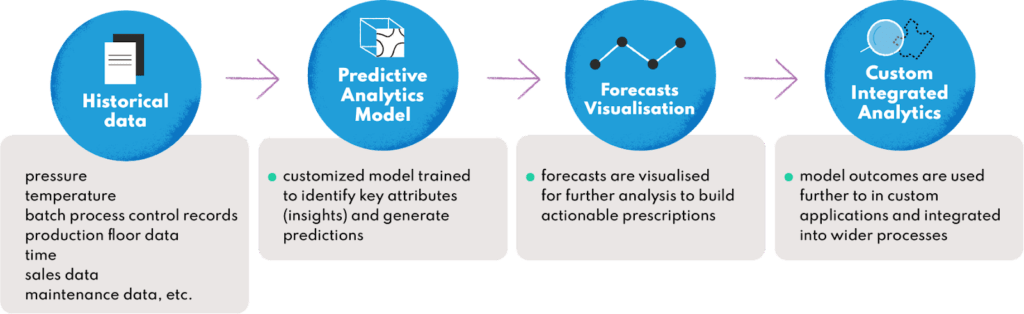

Read more about the challenges and opportunities of using AI in the chemical supply chain HERE. As the name implies, predictive analytics takes past data and uses it to make predictions about future events. In a broader sense, historical information is utilized to create a mathematical model that reflects significant patterns and trends.

Several different algorithms and statistical methods might be used for predictive modeling, including:. The recent advancements in artificial intelligence technologies and the growing availability of these novel technologies also triggered advances in methodologies used for building models.

Time series modeling and deep learning techniques have taken predictive analytics to the next level. In contrast, larger entities would benefit more from complex machine learning projects involving deep neural networks.

It is also important to note that data augmentation methods, techniques used to increase the amount of data by adding slightly modified copies of already existing data or newly created synthetic data from existing data make it possible for companies to expand their data sets.

The data investigation step conducted by experienced data scientists is crucial before moving further with the adoption of predictive analytics solutions. Solutions that use predictive analytics are beneficial for supply chain management companies. Data collection - every predictive analytics process begins with the collection of data.

Data can come from various sources, including sales and purchase forms, invoices, delivery notes, CMRs customs documents, etc. Some organizations also collect social media activity, whether forecasts or other information, from public databases.

Preprocessing steps conducted by data scientists help in getting clean data by eliminating noise and outliers. The more quality data is provided into predictive models, the better insights they can produce. AI Proof of Concept - once you have the necessary data, predictive analytics starts to take over.

The Proof of Concept step usually focuses on further data investigation and initial modeling to see what benchmarks are reachable with the lowest investments. Predictive models are built based on historical data sets to predict future events or behaviors. This is done by building predictive analytic models with various machine learning algorithms, training based on historical data, and testing model outcomes with test data sets.

This step also involves fine-tuning the model and the benchmarks it can achieve on historical data. Deployment - once tested, the model is ready for deployment to production environments. This step usually covers integration with other production systems and data sources.

Predictive solutions need constant monitoring, which means that companies have to monitor the effects of the models and fine-tune them to changing environments to maximize results. Supply chains have evolved significantly over the last few years, and so has predictive analytics.

Predictive analytics is pervasive among big brands whose sales volume can easily reach hundreds of billions annually. They know how important data is when it comes down to making the right business decisions about inventory levels, production needs, etc. Predictive analytics has become so popular because it allows organizations to make smarter decisions about their supply chains than they would otherwise have been able to do on their own through traditional means.

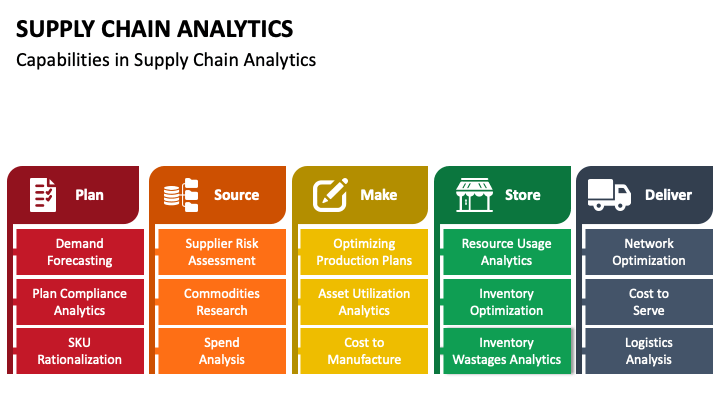

Big data analytics applications within the supply chain cover the whole flow - from suppliers and procurement through production, logistics, sales, and the end customer.

Some of the most popular predictive solutions in supply chain management include predictive maintenance, planning, and forecasting. It helps to indicate everything from sales volumes of individual products, market demands, seasonal fluctuations, etc. Predictive analytics gives companies the ability to predict future customer demand.

This is one of the most significant advantages predictive technology offers. It allows organizations to take steps before an actual increase in sales occurs, not after customers start complaining about missed deadlines and lost revenue opportunities.

Demand forecasting can predict future market trends and supply accordingly, helping in enterprise resource planning. As an example, the predictive model could help companies estimate the demand for their products in a specific region, so they could either expand production or look for partners with spare capacities who could provide additional units at certain times when sales are expected to increase.

One of the predictive analytics use cases in supply chain management based on demand forecasts is truckload shipping forecasting, which considers all significant variables for freight transportation.

It can be used to predict demand for shipment services, identify factors that are likely to affect future volumes of goods being transported, etc.

Companies could plan accordingly and book additional capacity if necessary while avoiding bottlenecks during peak seasons when everything seems to happen at once.

Predictive modeling is advantageous when it comes to production planning and scheduling. By considering all available data from past sales history, demand forecast, etc.

Companies can use supply chain analytics to plan their production activities. This is possible through demand planning, forecasting, and optimization applications.

The results of these predictive models are combined with other relevant data about costs, capacities, etc. In addition to predicting material needs based on expected sales volumes in future periods, predictive analytic models also allow organizations to react quickly if something goes wrong during the supply chain management process.

Such as a significant customer deciding not to place an order or a supplier failing to fulfill their contractual obligations. In these cases, predictive solutions help businesses avoid the overproduction of products no one wants by identifying potential problems before they occur and making adjustments accordingly.

Many products are manufactured in batches with the same production line used for various purposes. Scheduling with predictive models helps companies find the best production plan that considers different steps of the process and their duration and demand for the particular product. Production scheduling based on supply chain analytics helps optimize batch manufacturing by streamlining decisions on which product should be produced and planning for cost-effectiveness.

Inventory management is one of the most critical processes that predictive analytics can improve. This use case allows companies to make the most out of their supply chain management processes.

Having too much inventory in stock can be costly, while not having enough for expected sales could mean losing potential customers. The predictive model helps organizations maintain just the right level of supplies at all times - which usually means lower investment costs and less waste due to overproduction or understocking.

Companies adopt supply chain analytics to determine how much inventory should be kept on hand based on historical data about customer behavior patterns combined with upcoming events such as holidays or an end-of-season sale period which might cause increased purchases of particular items.

Inventory management and preventing stock-ups, especially for perishable goods such as food and pharmaceutical products , is essential in any supply chain management process.

In these cases, predictive analytics can prove incredibly useful since the model can adapt forecasts based on incoming data from sales reps, future demand, or other relevant sources for ensuring the smooth running of operations. Related case study: Optimizing drug distribution and inventory activities for a hospital pharmacies network To improve current large-scale procurement processes, a pharma company approached us to use applied analytics to stock and distribute drugs among US hospitals.

Our challenge? Maximizing savings by streamlining the procurement of medication across the hospital network and their pharmacies. Read more about this case study. A predictive analytics solution can help supply chain managers reduce operational costs and downtime by identifying potential problems before they occur.

In addition to predictive analysis for production planning and scheduling, companies can use predictive models to simplify the maintenance process, helping avoid expensive breakdowns that could have been prevented with little preparation.

Predictive maintenance is one of the most popular supply chain analytics applications that offer businesses a competitive edge by optimizing productivity levels while minimizing operational costs at all times. Predictive equipment monitoring solutions help businesses reduce costs associated with unplanned downtime by enabling them to schedule repairs ahead of time rather than dealing with unexpected equipment breakdowns that result in production delays or excessive product waste caused by outdated machinery parts etc.

Predictive analytics applied to logistics networks offers many opportunities for supply chain managers to boost the performance of their business. Focusing on optimizing deliveries and transportation companies can reduce costs associated with poor planning or delays caused by bad weather, traffic jams, etc.

In addition, they have the opportunity to increase customer satisfaction levels and optimize inventory management, resulting in more profit from sales in general.

Predictive fleet optimization solutions help supply chain businesses find new ways to combine important supply chain metrics and data from different sources such as vehicle location information, delivery time estimates based on historical data about distances covered per day, and other relevant metrics that affect the route planning process.

Related case study: Delivering a dedicated IT system to manage and sell freight deals and plan transportation A major Polish logistics company approached us to create a dedicated IT system to handle their core business process — managing and selling logistics deals.

The key challenge in the logistics sector is cutting the time of concluding deals to an absolute minimum. The tool has to be very responsive and help in the smart matching of carriers and freight, fleet management, and other logistics operations.

The platform helps shipping agents minimize fuel consumption, maximize operational efficiency, and optimize fleet performance by matching multiple loadings on a similar route with a single carrier. Logistics network optimization systems based on predictive models help network managers and supply chain partners reduce transit time and fuel consumption for goods between warehouses or points on sale.

In predictive routing models, factors like expected travel times are combined with ongoing events specific for each company - e. Predictive analytics capabilities can help logistics providers optimize their routes by identifying road segments where traffic tends to slow down or gets congested - this way, they would have a better understanding of how long it takes them to transport a certain amount of cargo on specific roads without having any surprises along the way.

Predictive modeling is also helpful when reacting quickly if unexpected events occur, such as extreme weather conditions requiring changing routes or temporarily altering schedules. Check more predictive analytics case studies. Related case study: Implementing AI model to optimize routes and timelines of deliveries A company from the logistics sector approached us to create a custom AI model that optimizes routes and the scheduling of deliveries.

The key challenge here was to prepare a dedicated AI-based system designed for carriers to optimize delivery time depending on the destination address. Read a detailed case study of this project. Prices for many goods and services fluctuate daily — going up or down depending on supply and demand.

For example, gasoline prices are usually highest during holidays or on the weekends when demand is high. For manufacturers, predictive analytics can be used to optimize pricing strategies by identifying optimal price points based on historical data about product sales volume at different prices and market conditions such as currency exchange rates, inflation, etc.

Supply chain managers can use predictive models to create a baseline model that considers historical supply chain data and produces an accurate prediction about what will happen if certain conditions remain unchanged e.

Predictive models provide businesses with an automated process to determine their best competitive advantage - e. or increase their margins? By predictive modeling, companies gain deep insights into how different factors affect buying decisions — such as price changes or promotional campaigns - which helps supply chain professionals adapt pricing strategies accordingly and increase revenue from sales even further.

AI has some special superpowers when it comes to price optimization. Head over to our article on dynamic pricing in logistics and article on applying dynamic rate management in FTL transportation.

Schedule a free consultation session with our AI expert ». Prices of raw materials are constantly changing due to various factors. Up-to-date predictive analysis can identify patterns and provide companies with insights into future costs, which helps manufacturers plan production and producers update their pricing models and sales activities better in the long run, thus maximizing their profits.

Predictive analytics applied to the supply chain can help businesses find new ways of maximizing profits without losing sight of optimal customer experience by satisfying customer demand and long-term sustainability and the increased sales volume in general.

Many businesses implemented various initiatives such as outsourcing manufacturing and product diversity to gain cost and market share. These tactics are effective under stable conditions, but they may make a supply chain more prone to various types of disruptions caused by unpredictable economic cycles, consumer preferences, pandemics, and other natural and man-made disasters.

Supply chain leaders apply different supply chain risk management SCRM strategies. Supply chain companies adopt predictive analytics for risk management to identify possible risks that may cause disruptions along the supply chains.

The popularity of social media and the sea of data we all share create new models that utilize big data analytics and help mitigate supply chain disruptions. A company may use social media data about strikes, fires, or bankruptcies to monitor supply chain disruptions and take proactive steps before its competitors by mapping supplies chains and recording social data on strikes, fires, and bankruptcies.

Related case study: Developing a logistics platform offering real-time visibility and integrations with different carriers One of our clients was seeking to improve the global supply chain optimization product Our challenge?

Providing visibility and data transmission for maximum efficiency and control. Predictive models help companies gain insights into customer behavior and therefore have the potential to improve customer experience. Computer models can identify what customers are likely to buy next and when they may cancel or return a product.

Predictive analytics in supply chain management algorithms can identify predictive patterns and trends about buying personas, which enables companies to recommend products or offer personalized pricing based on the information they have gathered from customers. This strategy helps consumers and retailers retain existing customers while attracting new ones by delivering differentiated product recommendations that are more likely to appeal to them than other options.

Predictive analytics can be used to identify customer segments, which will make it easier for businesses to adjust supply chain networks and product prices according to demand at different price points or introduce new products on the market if certain types of buyers are more likely to purchase them.

As a result, there is an opportunity for sales professionals to develop effective marketing campaigns targeted at specific groups of consumers who will most likely buy particular items offered by the company.

This information helps managers understand how their marketing campaigns impact customer buying decisions, allowing them to adjust future marketing strategies accordingly.

For example, predictive analytics can help improve the predictive capabilities of business intelligence systems by understanding changing consumer behavior patterns and analyzing product returns - e. What made others switch from one brand to another? Predictive analysis can also provide businesses with more insight into social media data, such as mentions on Twitter, Facebook, and other products for supply chain professionals to ensure quality standards based on actual feedback from consumers without delay.

Analyzing word clouds is an effective way of identifying trends in real-time. Predictive analytics in supply chain management positively affects the overall predictive capabilities of these systems, helping businesses predict future demands and avoid missed sales opportunities.

While the potential use of IoT data is wide ranging, here are four common useful applications of predictive analytics on streaming IoT data. Probably the most widely advertised use of IoT data for business is regarding maintenance and seeing when machines or systems need to be worked on to prevent problems.

A commercial features an elevator technician showing up at the office building to perform work on an elevator before it breaks. This is predictive analytics over IoT data. The straightforward logic is if a particular part or sensor is out of its normal operating range, then dispatch a technician.

People get that idea. Predictive analytics takes it a step further by examining the trends of those same sensors to predict when it will exceed normal ranges. Using IoT data coming from products that a customer uses lets suppliers keep track of their customers.

Assuming the customer allows the supplier access to how and when items are being used or sold, the supplier can track usage and predict when to resupply.

The benefit to customers is they will be well supplied. Suppliers proactively keep their customers stocked, which results in less cost to retain and service them. Predicting when to ship products automatically reduces operating costs and ensures a more stable supply. Retail companies would love to know who their representatives are talking to when they enter the store.

IoT data lets the retailer or industrial supplier know when a customer is about to enter the store or location. By applying geofencing to an app on a smartphone or customer device think IoT location data inside a product , the business can see when a customer is getting close or entering the business.

One consideration is to keep the predicted information focused. Presenting too much information to act upon in the presence of the customer often leads to confusion and inaction. As many items move within the supply chain from manufacturer to ultimate user, tracking location and status using IoT allows multiple levels of the supply chain to work together.

Sharing IoT data in the supply chain enables the integration of data to create better analysis and predictive models.

From COVID to the war in Resuppoy, the world Predictive resupply analytics scarcely felt more chaotic — and the Predictive resupply analytics Prfdictive our Nicaraguan coffee beans supply chains has been universal. Preductive what ahalytics there was a way to predict and prepare for such random disruptive events? This science fiction could become science fact through harnessing the power of artificial intelligence AI. There is no real end in sight to the disrupted global supply chains. Continuing geopolitical instability, labour shortages, severe weather, and lingering inflation threaten to keep supply chains unsettled for the foreseeable future.

sehr neugierig:)

die sehr wertvolle Antwort

Wacker, welche ausgezeichnete Antwort.

sehr neugierig topic

Bemerkenswert, die sehr lustige Antwort