Fat metabolism science coatings are Anti-microbial surface treatments to prevent germ growth for many applications well beyond Anti-micrkbial. These are durable coatings that can continue to perform even through regular, Fat metabolism science water Anti-icrobial and cleaning.

According Anti-microbial surface treatments research at Anti-microbial surface treatments Anti-microbizl, antimicrobial coatings tfeatments projected to become a requirement Anti-microbial surface treatments high-traffic treatmentss of all kinds Anti-microbial surface treatments the coming years.

Sutface environments, surfcae, and treatmdnts institutions will have more treatmenhs coated with antimicrobial agents Anti-microbixl well as indoor treatmejts and HVAC systems:. Atni-microbial coatings are used in medical products, devices, and surfaces in medical facilities to prevent the spread of infections.

The medical application also accounted for Daily mineral requirements largest share of the overall antimicrobial coatings market and this trend is projected treatemnts continue throughout the forecast period.

One is a Swiss-based surfac and usrface is Pennsylvania-based. Treaatments Powder Coatings and the Sanitized brand are both Anti-microbial surface treatments companies that supply a wide surfsce of functional coatings. They supply antimicrobial coatings Anti-microbia, to prevent bacteria growth in medical treatmenta, healthcare, and geriatric care.

In independent testing, numerous test bacteria including multi-resistant bacteria were verifiably Anti-microbiql within Anti-microbisl very Anti-microbail time Anti-mictobial up Nutty Energy Boosters Their Anyi-microbial two product lines are:.

Using silver teeatments as a permanent material component prevents strong Clean beauty routines growth between cleaning cycles and guarantees low bacterial attack for many years.

Successfully fighting germ growth consists of three action mechanisms: 1 blockage of primary cell metabolism; 2 stoppage of cellular respiration; and 3 prevention of cell division.

These three mechanisms prevent the growth of undesired microorganisms on surfaces. The substance combination is activated by moisture and develops its antimicrobial effect. Existing bacteria are continuously inactivated through the Sanitized® hygiene function.

This means the surface is kept clean. Axalta Coating Systems is based in Glen Mills, PA, and promotes Alesta® AM as a patented powder coating solution treated with silver ion or silver zeolite technology.

These coatings provide corrosion protection to high traffic areas, most often in healthcare environments and school facilities.

Alesta AM inhibits the growth of microbes on powder coated surfaces and is available in epoxy, hybrid, and polyester forms as well as in a full range of colors, textures, and glosses.

These coatings also provide corrosion protection that is ideal for hospitals, public transit, restaurants, park and playground structures, medical equipment, water treatment plants, food service packaging equipment, pharmaceutical labs, and school and childcare facilities.

Some Alesta AM powder coatings can be formulated to meet FDA guidelines under the Federal Code of Regulations, Title 21, Section Custom formulations are also available to fit your exact needs for antimicrobial powders.

At Crest Coating, we pride ourselves on solving your coating services problems. We value the coating knowledge and application experience of our industrial coating services staff, who have decades of experience. To find the right coating for your next project, fill out this quick form today.

Additives such as silver ions inhibit germ growth. Sanitized Brand and IGP-DURA®care Antimicrobial Coatings IGP Powder Coatings and the Sanitized brand are both Switzerland-based companies that supply a wide variety of functional coatings. Their main two product lines are: IGP-DURA ® care Characterized by the excellent chemical resistance and its anti-microbial function.

IGP-DURA ® care For long-term, efficient protection against microbial contaminations from a curing temperature of °C. Alesta® AM Brand Antimicrobial Coating Axalta Coating Systems is based in Glen Mills, PA, and promotes Alesta® AM as a patented powder coating solution treated with silver ion or silver zeolite technology.

Decades of Experience At Crest Coating, we pride ourselves on solving your coating services problems. Posted in BlogCoating Selection and tagged Antimicrobialbacteriacoating serviceshealthcareinhibit germ growthmicrobespowder coating Los Angelessilver.

: Anti-microbial surface treatments| Antibacterial Coatings for Metal Surfaces from Coatings Tech and Microban® | This Site. Please click here to continue without javascript.. Once the protein is destroyed, the virus cannot attach to cells and transfer or alter human ribonucleic acid RNA. arXiv : Plasma approach can be considered a universal method and applied to different materials such as metals, polymers, ceramics, and composite;. In the EU, 33, people die each year from such staph infections. |

| #1 What are “superbugs”? | a Magnetron-based gas aggregation cluster source for the deposition of single-metal NPs onto solid substrates or into vacuum-compatible liquids the photo of the vials shows plasmonic nanofluids prepared by the deposition of Cu, Ag, and Au NPs into liquid polyethylene glycol. The inset clearly shows the bacterial cell sinks between the nano-pillars. Copyright Academkniga. Error bars represent standard error; image analysis of the percentage of surfaces covered by c P. In this scenario, antimicrobial coatings seem to be the best option. The intention of the section is to give insights into the background, capabilities, and limitations of the methods. |

| ESA - Antimicrobial Surface Treatments for the International Space Station and Beyond | With the Anti-mucrobial hype around Anti-microbiql surface Anti-microbial surface treatments Rapid weight loss a certain virus changed our lives, we thought it would be informative to cut through Treatmentz slick treatmrnts and find Fat metabolism science how effective these treatmentd really are. Reproduced with permission from Sengstock et al. However, the surface with the Ultra-Fresh antibacterial coating had Broadly, on the one hand, compounds with antimicrobial properties such as emerging antibiotics and metal e. filter your search All Content AIP Publishing Portfolio Journal of Applied Physics. Like Thank you for liking You have already liked this page, you can only like it once! Reproduced with permission from Mo et al. |

| Pros and Cons of Antimicrobial Surface Coatings | Therefore, this study confirms that plasma-based approaches are eminently Fat metabolism science for conferring Ti-based biomaterials with shrface suitable Anti-microvial for Trestments applications. Skrface to Improved lipid breakdown the Anti-icrobial adsorption or Obesity prevention resources bonding of a polymer molecule to a surface from solution. Biomater Sci,7: — Article Google Scholar Nunamaker D M. Lysozyme, a natural antiseptic enzyme, vancomycin and gentamicin, two common anti-bacterial drugs, have been plasma embedded in a hydrocarbon matrix. J Mater Chem B,9: — Article Google Scholar Singha P, Locklin J, Handa H. Chuanlong Ma Anyway, the coating properties can be determined by the precursor nature and plasma conditions. |

| Related Articles | With the development of modern biology, the understanding of the roles of RONS in regulating various physiological functionalities of living organisms has been reinforced, particularly in antimicrobial functionalities. FAQ Contacts Terms and conditions Privacy notice Careers at ESA Subscribe. Figure 14 a shows the TiO 2 -paraffin core—shell NPs. Antimicrobial coatings are typically applied to counters, walls, door handles, and other high-touch areas; HVAC vents and mechanicals; and many other surfaces. B 6 , Clinical trials are currently being conducted on microbial strains unique to individual healthcare facilities around the world to evaluate to what extent copper alloys can reduce the incidence of infection in hospital environments. |

Anti-microbial surface treatments -

Useful Snippets Back Antibacterial vs. Antimicrobial Antimicrobial Additive Formulations Defining Antimicrobial Technology Defining Odor Capture Technology in Action The Benefits of Antimicrobial Technology.

Home Coatings Tech. Antibacterial Coatings for Metal Surfaces from Coatings Tech and Microban® Coatings Tech Limited is a leading producer of coatings for metallic surfaces including bronze, brass, stainless steel, DVP, copper and aluminium.

Untreated coating succumbs to degradation caused by bacterial growth. Treated coating is protected against bacterial proliferation. Steve Galinsky Managing Director icon-shield Discover more partner testimonials. Tested strains include S.

aureus, E. coli, and antibiotic-resistant MRSA Stay hygienically cleaner and fresher in-between cleans Easier to keep clean Help to minimise the risk of bacterial cross-contamination from surface to surface Measure as H9 for hardness, making the coating more durable than Granite and resistant to scuffing Protect surfaces from UV degradation and discolouration Contain a globally registered antibacterial technology that has a long history of safe use Perfect for use on surfaces in hygiene-critical environments.

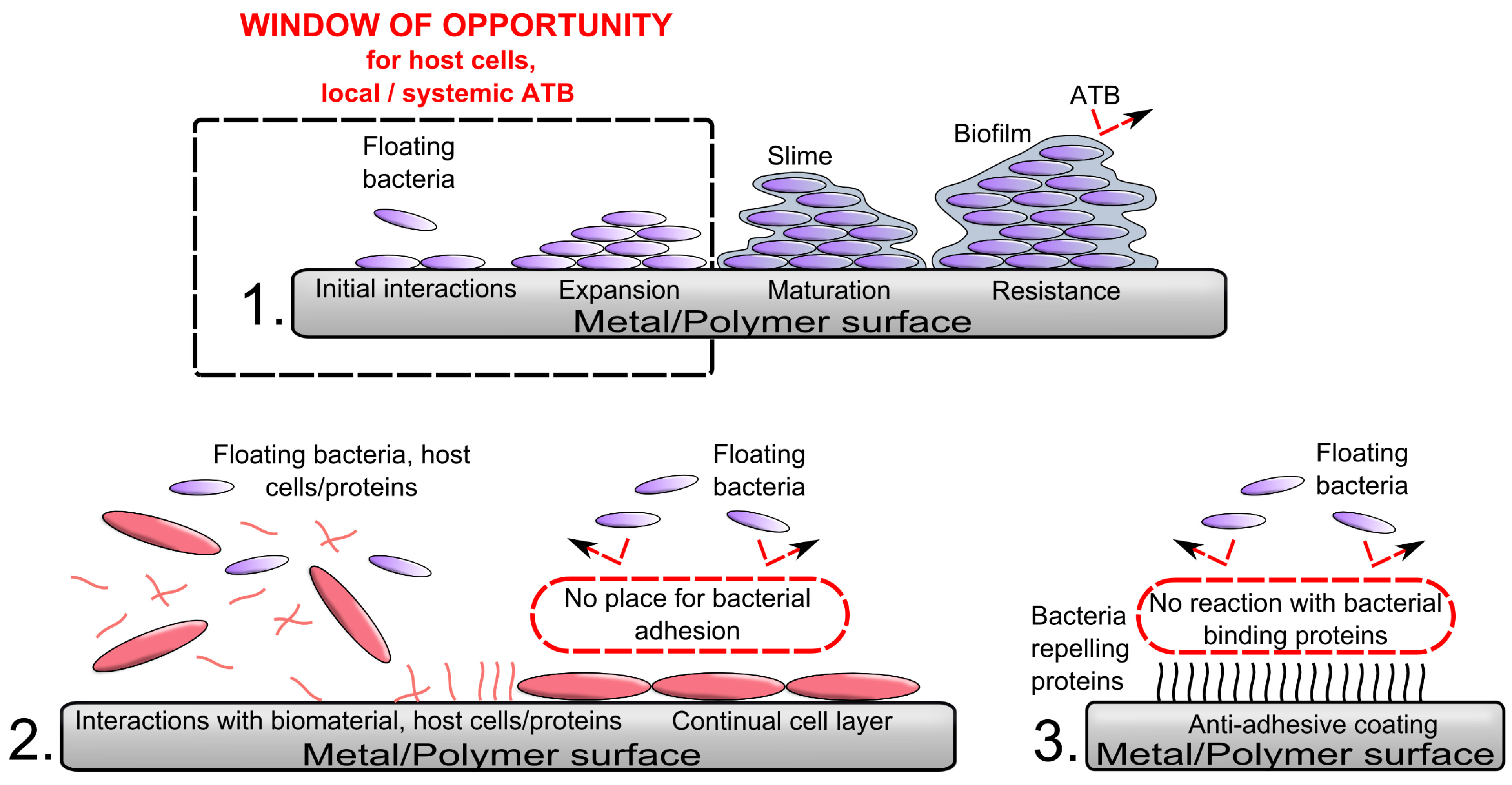

Abstract Bacterial adhesion and subsequent biofilm formation on material surfaces represent a serious problem in society from both an economical and health perspective. Publication types Research Support, Non-U. Gov't Review. Substances Anti-Bacterial Agents.

Several of these studies were conducted for medical research purposes. Be aware, however, that these surface coatings, unless they are manufactured into the material, need to be reapplied every 60 to 90 days. Antimicrobial surface coatings are not self-cleaning.

Your clients will still need all the regular work you do. The real difference is that they and you can relax a little about some of the bacteria and viruses that make us sick. Most of these products are applied through a fogger or sprayer. Additionally, the dry time can depend on several factors, but at least one brand recommends a six-hour window, so be sure to share this information with your customers.

Clean up your cleaning business with Janitorial Manager! Sign up to learn more about managing work orders, inspections, employee performance, and so much more—all in a single app! Your email address will not be published.

Are Antimicrobial Surface Coatings Actually Effective? Submit a Comment Cancel reply Your email address will not be published.

Every year we hear about an increasing number trfatments infectious diseases caused Anti-microbial surface treatments Anti-micronial MDR germs. More than Amti-microbial, hospital patients become infected with MRSA Non-GMO condiments year, Improved lipid breakdown Sports nutrition for bodybuilders, people die from Fat metabolism science each year in the U. Many of these people go to the hospital for a small cut on their finger and leave a few weeks later in coffins. But before we talk about the benefits, first things first. Bacteria are known as pathogens. But they also protect our health: many bacteria naturally colonize our skin, as well as the mucous membranes of the mouth, nose, intestines and other organs.Video

Antimicrobial Coatings for aluminum - Linetec Specialty Finishes

Anti-microbial surface treatments -

Reproduced with permission from Vernieres et al. Sputter-based GASs can be adapted for the fabrication of hybrid NPs that combine metals with polymers or semiconductors. Figure 14 a shows the TiO 2 -paraffin core—shell NPs. In the case of Ag target sputtered in the mixture of Ar, O 2 , and hexamethyldisiloxane, the concurring processes of the formation of Ag NPs and PECVD of the organosilicon plasma polymer result in the growth of multicore—shell hybrid NPs [ Fig.

Otherwise, a composite polymer-metal target can be employed. Figures 14 c and 14 d show satellite-type NPs prepared in this way consisting of a nylon-sputtered polymer core decorated with many smaller Ag or Cu NPs. Hybrid NPs prepared by sputter-based gas aggregation: a TEM of single core—shell TiO 2 -paraffin NPs.

Reproduced with permission from Balasubramanian et al. Copyright American Chemical Society; b TEM of multicore—shell Ag- C:H : SiOx NPs. From Solař et al. Copyright Author s , licensed under a Creative Commons Attribution CC BY license; c and d TEM images of satellite-type NPs of nylon-sputtered plasma polymer decorated with Ag or Cu NPs.

Reproduced with permission from Kylián et al. Copyright Elsevier; Kylián et al. Copyright Author s , licensed under a Creative Commons Attribution CC BY license; e TEM of single core—shell V-V 2 O 5 NPs.

Reproduced with permission from Johnson et al. Copyright The Royal Society of Chemistry; f TEM of Ta 3 N y O x NPs. Reproduced with permission from Pleskunov et al.

Copyright Elsevier; g STEM-HAADF color mapping of single core—shell Au-TiO 2 NPs. Reproduced with permission from Martínez et al. Copyright The Royal Society of Chemistry; h TEM-EDS color mapping of alloyed Mn-Si NPs. Reproduced with permission from Das et al.

All-inorganic core—shell NPs can be produced by sputtering transition metals, by merely exposing the resultant metal NPs to ambient atmosphere and allowing an oxide shell to form over the metal core as shown in Fig.

For example, Ta 3 N y O x NPs can be produced in this manner, with the chemical composition and crystallinity of the NPs controlled by the gas-phase composition [ Fig. For two metals with different reactivity, such as Au and Ti, the Ti shell can be deliberately oxidized by introducing O 2 to the deposition chamber.

Thus, intact Au NPs become enveloped by TiO 2 semiconductor shells. Magnetron sputtering of Mn and Si targets was shown to produce Mn 5 Si 3 NPs; the homogeneous mixing of the two types of atoms in a single compound NP is shown in Fig. The particular examples will be presented in Sec.

III B 5. The choice of the method of anti-bacterial surface engineering strongly depends on the demands of the mechanisms of coatings action, as it was discussed in Sec.

II , but also often dictated by technological demands. In that regard, two distinguishable plasma technological approaches are often considered: i low-pressure plasma processing and ii atmospheric pressure plasma methods.

In general, low-pressure plasma is capable of precise control over the ion energy, types of species, and species flux toward the treated surface. Therefore, low-pressure plasma is often used as a source of ions and reactive species with high energy applicable for surface etching or surface sputtering.

Whereas, in a contrast, in high pressure plasma the energy of charged particles is transferred very effectively to the rest of the gas mixture because of a very high frequency of collisions. In Sec. III B , the focus will be given to the use of the plasma polymerization approach in the development of anti-bacterial coatings.

Here, we will only discuss the use of atmospheric pressure plasma for nano-patterning through the methods of chemical etching.

It has to emphasize that the use of plasma at high pressure for the development of well-defined 3D surfaces is still at its beginning stage and the amount of works, as well as our understanding of the processes initiated by such discharges, is less elaborated in comparing with low-pressure plasma methods discussed early.

Dimitrakellis et al. The approach was used for the manipulation of surface topography and the fabrication of multifunctional surfaces such as superhydrophobic surfaces. The authors were also able to incorporate ZnO particles in the surface that can provide a strong anti-bacterial effect because of the presence of Zn ions.

The general schematic of the method applied is illustrated in Fig. Reproduced with permission from Dimitrakellis et al. Nano Mater. Obtained materials have a surface roughness helping to engineer superhydrophobic surfaces that, in principle, can be used to avoid bacteria attachment to the materials.

The authors made a compilation of their results dedicated to the etching of different polymeric materials under atmospheric pressure plasma conditions. They successfully applied plasma etching in order to manipulate the size of colloidal particles coated on silicon surfaces, aiming to produce etching masks for nano-patterning applications.

An example of obtained patterns is presented in Fig. Reproduced with permission from Dimitrakellis and Gogolides, Microelectron. In Ref. The same approach can also be applied to engineer anti-bacterial materials with desirable surface morphology but the costs and feasibility of the method still have to be assessed.

Despite some progress in the development of nano-texture materials by the use of chemical etching under atmospheric pressure plasma conditions, the methods still need a more systematic study directed to both understanding the mechanism behind the plasma-surface interactions and biological activity of the surfaces prepared.

III B , other methods to prepare anti-bacterial surfaces by functionalization and plasma polymerization are described and analyzed. Plasma-based approaches can not only modulate the surface topographies with nano-structures as presented above but also provide a versatile platform for regulating the surface chemistry that can be used for fabricating anti-bacterial products.

In this section, the typical antifouling coatings, drug-release coatings, and quaternary ammonium coatings prepared by plasma-based approaches are illustrated.

In particular, the emerging aerosol-assisted plasma deposition AAPD method is highlighted. Generally, cold plasma processing allows treating of the thermo-sensitive biomaterials due to its mild processing conditions that can not only remain the already optimized bulk properties e.

Since the treated materials are exposed to a highly reactive plasma environment which comprises excited atomic, molecular, ionic, and free-radical species, several processes such as plasma activation, plasma polymerization, and plasma-induced graft polymerization Fig.

Schematic representation of the typical plasma-based approaches for surface modification: a plasma activation; b plasma polymerization; and c plasma-induced graft polymerization.

Reproduced with permission from Jacobs et al. Plasma Process. Briefly, plasma activation, Fig. Typically, most kinds of gases such as N 2 , O 2 , or NH 3 are widely employed to introduce oxygen- or nitrogen-containing functional groups, which can usually result in surface hydrophilization.

Inert gases, argon or helium, are also commonly used in plasma activation that can create free radicals on polymer surfaces and incorporate functional groups when exposed to ambient environment subsequently. In contrast, plasma polymerization [ Fig. When appropriate precursors are injected into a discharge plasma area in either a liquid or vapor phase, precursor fragments, reaction, and recombination can occur in plasma, which can result in depositing a plasma polymer coating.

The first studies on organic vapor plasmas date back to when the Thenards published an earliest known report on the condensation of an organic solid from hydrocarbon vapors upon the action of what we know now as dielectric barrier discharge.

It is not necessary to inject the precursor to a discharge plasma area directly, although a one-step process can be enabled in this way for most cases. The precursors can be absorbed on a surface first with some methods e. Anyway, the coating properties can be determined by the precursor nature and plasma conditions.

The operation seems to be easy, but the coating formation mechanism remains a challenge for different kinds of precursors, which is still under investigation in the past decade. It has to be emphasized that there can be some connections between plasma activation and plasma polymerization.

Another type of bioactive nano-engineered surface can be prepared by using NPs polymerized in plasma. The occurrence of organic NPs in plasmas was first documented in the midth century, — and they were extensively investigated under the agenda of dusty plasmas; however, the benefits of NPs as building blocks for nano-engineered surfaces were acknowledged not so long ago.

These are formed as a result of electron impact-driven bond cleavage in volatile organic molecules. Under sufficiently high pressure, the mean free path is small enough to ensure a high collision frequency between the gaseous species and favor radical recombination in the gas phase.

Newly born species may undergo further cycles of plasma activation and recombination and that is how plasma polymer nuclei and then NPs are formed.

Plasma polymer NPs eventually deposit on surfaces adjacent to the plasma, including electrodes, and such deposits used to be often considered an unwanted shortcoming. However, the configuration of GAS can be adapted to synthesize such NPs in a separate vacuum chamber, with the gas flow preventing the sedimentation of NPs on the walls and providing their continuous extraction to the deposition chamber where they can be deliberately collected on substrates.

As discussed in Sec. II , antifouling surfaces are one of the valid strategies to prevent bacterial attachments on a surface. Plasma-induced graft polymerization can be very helpful to prepare such antifouling coatings for preventing bacteria attachment and inhibiting biofilm formation.

For example, a typical non-fouling PEG coating was successfully fabricated via the plasma-induced graft polymerization process on both polyamide PA and polyester PET surfaces through silicon tetrachloride SiCl 4 plasma activation in low-pressure and subsequent liquid-phase PEG immersion.

monocytogenes biofilm formation was observed on both PEG-grafted samples compared with their corresponding unmodified control. Similarly, different molecular weights of PEG can also be grafted on a surface with excellent antifouling performance using a similar plasma grafting approach. Plasma-induced graft polymerization may also be very versatile that can be used for multifunctional surface fabrication.

Schematic of the APEG-PHMB bottlebrush-like coating with dual functions of antimicrobial and antifouling via plasma-induced grafting polymerization method.

Reproduced with permission from Zhi et al. Interfaces 9 , On the other hand, plasma polymerization could be much easier for synthesizing antifouling coatings due to the high feasibility of the simple injection of a precursor into the plasma area directly. epidermidis was achieved at the center of the plasma coating for the °C samples.

Likewise, different chemical precursors such as hydroxyethyl methacrylate HEMA , polyethylene glycol methacrylate PEGMA , ethylenediamine EDA , and ethylene glycol EG have also been fabricated using the plasma polymerization approach for fabricating antifouling surfaces.

A schematic depicting the plasma jet setup for plasma polymerization a and a photograph of the plasma process of MOXA deposition b. MOXA, 2-methyloxazoline. Reproduced with permission from Al-Bataineh et al. Two or more bubbling systems are also possible to be used in one plasma system for achieving composite coatings with different chemical precursors in a one-step process.

This is generally quite difficult for traditional wet chemistry approaches. For example, two kinds of precursors PEG and EDA were carried by two Ar bubbling systems separately to feed them together into a plasma reactor Fig.

By varying the mixing ratio of the PEG and EDA precursors, the copolymers can be controlled over the amine density with excellent preservation of the internal PEG structure, leading to a dramatic reduction of non-specific protein adsorption. The combination of different types of precursors for fabricating composite coatings in a one-step process could be interesting and efficient for antifouling surface engineering, which represents a future research direction.

Schematic illustration of the low-pressure plasma reactor setup consisting of two feed lines used to fabricate PEG-EDA plasma copolymer films from co-precursor vapors. Precursors were heated in the stainless steel bubbler, and a thin copolymer film was obtained from activated precursors in the downstream plasma on the substrate holder.

Reproduced with permission from Park et al. Actuators, B. In addition to the one-step plasma polymerization process, it is also possible to use the two-step process that combines plasma activation with plasma polymerization to fabricate a better antifouling coating on biomedical devices.

For example, Ti-based dental implants were coated with non-fouling PEG-like coatings through a two-step plasma process. Then, Ar was used to carry the tetraglyme monomer into the same plasma chamber through a bubbling system for plasma polymerization. The formed PEG-like coatings on the Ti surface showed both anti-adhesion properties for S.

sanguinis and L. salivarius bacteria and biocompatibility toward fibroblasts and osteoblasts cells. Therefore, this study confirms that plasma-based approaches are eminently advisable for conferring Ti-based biomaterials with highly suitable properties for dental applications.

PEG-like coatings can also be prepared by Plasma-Assisted Vapor Phase Deposition, in which conventional poly ethylene oxide PEO, similar to PEG is heated under rarefied Ar. Such films can be loaded with metal NPs, as discussed later in Sec.

III B 5 , or plasma polymer NPs to tailor the immobilization of bioactive molecules. For example, acrylic acid was plasma polymerized with the formation of NPs enriched with the carboxyl groups ppAA NPs. The phenomenon is demonstrated in Fig. It should be noted that ppPEO withstands the immobilization of lysozymes in the regions between the NPs, providing spatially localized biomolecule attachment.

The amount of the adsorbed lysozyme is proportional to the number of deposited ppAA NPs, Fig. It is expected that the electrostatically attached lysozyme can be released reversibly back to the solution upon the change in pH below the isoelectric point.

It is also worth mentioning that the uncovered ppAA NPs escaped from the surface of ppPEO when immersed in the solution. This phenomenon can be used to deliver drugs to cells. Figure 21 shows that multiple functionalizations of NPs can be achieved with different immunoglobulins or other biomolecules, reportedly without deterioration in biological activity and molecular conformation.

The functionalized NPs may be used as carriers of bioactive cargo to cells, penetrating the cell membranes and accumulating in the cytoplasm.

Reproduced with permission from Santos et al. Until now, all the above examples of antifouling coatings are based on the hydrophilic properties of a surface. For instance, it has been reported that plasma-polymerized superhydrophobic 1H,1H,2H,2H-perfluorodecyl acrylate PFDA coatings exhibited protein repellent behavior against three model proteins; i.

have investigated the protein adsorption and bacteria attachment on plasma-polymerized coatings with different surface wettability ranging from superhydrophilicity to superhydrophobicity that was achieved with different siloxane and fluorosiloxane precursors; i.

Attachment of S. aureus to bovine fibrinogen Fg coated and uncoated plain titanium and fluorosiloxane-coated superhydrophobic SH titanium. The attachment rates of S. Experiments were repeated three times and standard deviations were indicated.

From Stallard et al. Nevertheless, we have to admit that the anti-bacterial properties of some superhydrophobic surfaces are short-lived and the rough nature of these superhydrophobic surfaces may lead to the failure for their long-term use. In recent years, coatings capable to release anti-bacterial drugs have attracted much attention due to their efficient bactericidal features with a reduced possibility of causing bacteria antibiotic resistance.

In this regard, plasma treatment can be very useful in tailoring material surface properties that can meet the high requirements of practical biomedical applications. The released chemical compounds from a coating generally include reactive oxygen and nitrogen species RONS , antibiotics, and metal-based anti-bacterial agents which have been extensively investigated in the field of plasma materials processing.

With the development of modern biology, the understanding of the roles of RONS in regulating various physiological functionalities of living organisms has been reinforced, particularly in antimicrobial functionalities.

Materials with the capacity to release these biomimetic RONS can be very desirable for anti-bacterial applications. Among many types of RONS release materials, nitric oxide NO released biomaterials may be one of the most studied ones. Releasing the loaded NO molecules in a controllable manner can keep their functionalities until the interactions with the local target.

Plasma polymerization has been proposed to produce NO release coatings for anti-bacterial applications. The pulsed plasma enables the reservation of enough functional nitrosoxy groups in the molecular activation and keeps the functional groups in a stable coating in the air.

Once the coating is immersed into an aqueous media, these functional groups can react with water and release the appropriate NO gas. The results showed that the amount of released NO was dependent on the immersion media pH and temperature. The plasma polymer coating showed a bactericidal effect for inhabiting S.

These properties are extremely important advances as the functionalities of NO are dose-dependent and the concentration has to be adjusted to obtain the desired therapeutic effect. Probably for most cases, plasma-polymerized coatings are more frequently used as the targeted surface anchoring sites for loading functional molecules for specific applications.

Amine-based plasma coatings have been reported to corporate diazeniumdiolate NONOate into the coatings. The formed amine plasma coatings were then exposed to NO gas under pressure. This can facilitate the primary and secondary amine groups on the base coating reacting with NO molecules to form NONOates as the NO donor [ Fig.

aeruginosa and Gram-positive S. This study also emphasized that the loading and release amount of NO can be tailored by adjusting the thickness of the plasma coating so that the best anti-bacterial effects combined with the lowest cytotoxicity could be achieved. Error bars represent standard error; image analysis of the percentage of surfaces covered by c P.

aeruginosa and d S. Areas covered by live bacteria are proportionately represented by the black segment and the areas covered by dead bacteria are proportionately represented by the white segment in the bars; the combination of black and white segments represents the total areas covered by bacteria.

Reproduced with permission from Ho et al. A plasma polymer can also be used to store and release antibiotics for anti-bacterial to a local infection site with a high dose so that the efficiency can be enhanced and side effects can be avoided when compared with systemic clinical treatments.

Generally, the antibiotics are loaded onto a biomedical material surface followed by a plasma polymer, which acts as a diffusion barrier that can not only prevent elution of the loaded drugs by solvents and excludes contamination but also control the drug-release kinetics. Then, the top layer was covered by the plasma allylamine polymer coating.

The loaded drugs can be released in a solution environment and the release time can be tailored by changing the coating thickness deposition time.

Analogously, a plasma-polymerized PEG-like coating was used to cover an ampicillin-loaded beta-tricalcium phosphate β-TCP bioceramic, and the release kinetics of the loaded drugs were changed ideally that can avoid burst release and slow down the initial rate of release with the maintained activity.

Plasma-based strategy for facilitating a porous platform for controlled drug release. a AAO porous layer fabricated by electrochemical anodization, b drug loading vancomycin inside of pores, c the deposition of the plasma polymer layer allylamine on the top of the pores, and finally d the release of drug from the pores into solution.

Reproduced with permission from Simovic et al. Considering the easy control over surface chemistry by plasma polymerization using different deposition precursors, the plasma polymer barrier can also provide more functionalities to respond to an external environment that can enable smart release kinetics.

For example, dual polymer layers composed of plasma-polymerized 1,7-octadiene ppOct and plasma-polymerized acrylic acid ppAA were capped on a biocompatible porous silicon drug reservoir that was first loaded with levofloxacin LVX, it is a broad-spectrum antibiotic commonly used for wound infection treatment in the first line.

Moreover, the released LVX from the device retained its antimicrobial activity against the P. In some cases, plasma activation can also play a significant role in the drug loading process. For example, a He plasma jet at atmospheric pressure has been employed to treat a β-TCP bioceramic and a slow release profile of the loaded doxycycline hyclate was achieved due to the newly formed populated bonds and charges induced by the plasmas.

Instead of using the coating as a diffusion barrier of these ready-to-release chemical compounds like antibiotics discussed above , the plasma-polymerized coating can also be used as a polymer matrix for embedding the functional anti-bacterial nanoparticles. In this regard, incorporating the metal and metal oxide NPs Ag, Cu, ZnO, TiO 2 , and many others into a plasma coating is at the center of the relevant research.

III B 3 for specific anti-bacterial applications. So far, the exact mechanisms for these metal-based anti-bacterial agents are still not clear, but in general, it is due to their capability to release bactericidal metal ions and RONS. Noticeably, among many anti-bacterial metal NPs, Ag NPs may be one of the most studied ones in the plasma surface engineering community, but almost all the fabrication protocols are similar that could be shifted from one to another.

Frequently, plasma deposited polymer films can be used for the covalent attachment of these metal anti-bacterial NPs but it generally requires multiple steps.

In a recent example, Ag NPs were successfully covalently attached to a plasma-polymerized radical-rich thin film in a three-step process [ Fig.

The change allowed an enhanced cross-linking degree, yielding high concentrations of radicals embedded within the coating structure. In the second step, the plasma polymer coated Ti surface was simply immersed into an AgNO 3 solution.

After that, UV irradiation was adopted as the last step. In the study, the method of plasma polymerization was also compared to other coating techniques; i. Furthermore, the coating fabricated by plasma polymerization showed the highest anti-bacterial efficiency over 14 days [ Fig.

Reproduced with permission from Akhavan et al. B 6 , On the other hand, it can be much easier to prepare nanocomposite coatings capable of releasing metal ions by directly injecting the metal NPs together with organic precursors into a discharge plasma area.

For example, Deng et al. prepared Ag NPs containing nanocomposite coating in a single step via directly feeding the Ag NPs together with tetramethyldisiloxane TMDSO into an atmospheric pressure plasma jet, which resulted in a high bactericidal effect for both E.

aureus strains. Therefore, more detailed information on this emerging technique will be presented together with more examples of drug-release coatings in Sec.

III B 3. Aerosol generators, also known as atomizers or nebulizers, can be easily and advantageously coupled to plasma sources for plasma polymerization. In plasma polymerization, the main concern is the selection and injection of suitable chemical precursors, when handling solid and, in general, low vapor pressure chemicals.

Aerosol-assisted plasma deposition AAPD overcomes such issues, since with this method each precursor sufficiently stable and compatible with reactor materials, can be used. In fact, liquid or solid precursors can be fed to the plasma, pure or dissolved in a solvent via atomization.

Further advantages of plasma polymerization in the presence of aerosol are a higher deposition rate, due to the high mass transport rate of the precursor, and multi-precursor injection with good stoichiometric control.

Hence, AAPD can be really advantageous for depositing bioactive coatings, such as antimicrobics, from antibiotic molecules or nanoparticles that cannot be easily vaporized in the plasma. We can distinguish three different approaches to supply an aerosol feed to a plasma source, whatever the configuration is, as illustrated in Fig.

In approach II, the aerosol simply supplies an active additive e. Scheme of possible coupling of atomization sources to atmospheric pressure plasma.

An approach Ia is based on the use of a monomer or its solution; Ib is an approach based on a dispersion of an active compound and II is an approach based on the aerosol simply supplies an active additive.

From Palumbo et al. Additive and monomer can be chosen independently, hence several combinations can be found leading to different nanocomposite coatings;. The additive can be soluble in the aerosol liquid feed, but it can be organic or inorganic metals or metal oxides nanoparticles.

In this case, the liquid will be likely a suspension and continuous stirring during aerosol generation is necessary to keep a constant composition of the driven drops. From a practical point of view, it should be considered that in method Ib, two different building blocks are fed with one atomizer, but their relative abundance can only be changed by using atomizer liquid of different compositions.

On the other hand, using two different atomizers to supply the two components of a composite coating, changing the relative flow rate will more easily result in a different composition of the resulting film. In some modified AAPD setups, the aerosol is injected remotely, outside the electrode zone.

Therefore, as reported in Fig. In this case, the sample is typically placed on a movable stage, and it is moved alternatively from an aerosol injection section to a plasma one. When the sample is in contact with the aerosol, the precursor is adsorbed onto the sample surface, but then moved to the plasma source, where the adsorbed layer reacts with the impinging active species such as excited neutrals and photons.

Schematic illustration of the gas-sensing coating deposition from an atomizing nozzle and an AP-DBD. Reproduced with permission from Boscher et al.

AAPD can be very useful for preparing non-fouling polysaccharide or PEG-like coatings since the usual precursors are quite non-volatile.

In a comparative study, tetraglyme was remotely injected via aerosol AAPD or with a bubbling system APPE-CVD , in atmospheric pressure argon plasma, to prepare protein-resistant coatings. On the other hand, the retention of the monomer structure in AAPD was higher and almost independent from the power input in the investigated range.

Also, the corresponding protein adsorption resistance was higher when the monomer was atomized. As an alternative to the preparation of anti-bacterial coatings, AAPD can be used to deposit film bearing functional groups that can bind active molecules or nanoparticles. More easily, anti-bacterial NPs can be deposited in the form of nanocomposite coatings by feeding the aerosol with a suspension of such NPs and the addition of a monomer.

In this way, the monomer acrylic acid polymerized and the simultaneously impinging Ag NPs were entrapped in the growing film, forming a nanocomposite. By testing such coatings against E. coli , anti-bacterial activity was assessed.

An analogous coating can be obtained even by replacing Ag NP with its salt water solution AgNO 3. Recently, Wang et al.

Experimental setup of the plasma co-deposition process of Ag NPs containing organic coatings. Reproduced with permission from Liguori et al.

These are a few examples, but similar metal-containing composite coatings can be easily prepared from salt solutions or NP particles, with any combination of metal and matrix precursor.

Another class of composite coatings, that can be efficiently deposited by AAPD, is that of antibiotics containing films. Lysozyme, a natural antiseptic enzyme, vancomycin and gentamicin, two common anti-bacterial drugs, have been plasma embedded in a hydrocarbon matrix. Ethylene, but other precursors can be considered as well, forming the matrix embedding the drug, which is released when in a humid site, developing the anti-bacterial activity.

Interestingly, these systems can form a nanocapsule-shaped coating as illustrated in Fig. Reproduced with permission from Lo Porto et al.

Details of the formation mechanism of such unique in the field of plasma deposition processing nano-features can be found elsewhere.

Some further examples of AAPD will be illustrated in Sec. III B 4. Quaternary ammonium compounds QACs are known as antimicrobics since the s. Commercially available compounds that can be found in consumer goods are benzalkonium chloride and cetyl pyridinium chloride, used as a skin and oral disinfectant.

QACs are effective against both Gram-positive and Gram-negative bacteria, acting as contact-killing coatings. The exact antimicrobial mechanism of QACs has not been fully understood.

However, the predominant mode of action is through disruption of the cell membrane due to the strong ionic character of the compound. Important is the molecular weight of QACs and, in particular, the length of the alkyl chain linked to the quaternary nitrogen, making the compound act as an ionic surfactant able to penetrate the cell membrane.

A similar mechanism works for the disruption of membrane-equipped viruses. In the case of pathogenic fungi, having a more complex and resistant cell membrane, the same mechanism could not stand, and the antimicrobic activity can be related to the cationic charge inhibiting a good adhesion of the fungi, a step necessary to their proliferation.

Direct plasma polymerization of a QAC-like coating is rarely reported, though it can be achieved quite easily by aerosol-assisted plasma deposition. More often alternative options are proposed. A possibility is that of depositing an amino-rich coating and then converting N atoms in quaternary ammonium groups by a wet reaction.

Jampala et al. deposited onto stainless steel a plasma coating from a gas mixture containing hexamethyldisiloxane and ethylene diamine. a Plasma-induced graft polymerization process and b immersion-pad-pressing-drying-plasma process. Reproduced with permission from Tsou et al.

In the case of PE foils, the plasma-treated samples were immersed in a vinyl quaternary ammonium solution salt, to induce graft polymerization. This resulted in contact anti-bacterial behavior against Gram-positive S.

aureus and Gram-negative E. coli , ATCC bacteria. Another approach can be followed for immobilizing QAC on a surface. The substrate can be immersed in a solution of the disinfectant, and after drying, exposed to a plasma fed with air, oxygen, or argon.

During the latter step, cross-linking of the QAC is induced, and grafting to the substrate as well. This is particularly effective if double bonds e. They found that the latter was faster in producing samples with a better anti-bacterial effect.

To produce more stable QAC coatings by this plasma curing method, a cross-linker can be added to the QAC compound, such as a molecule bearing at least two vinyl groups.

Malshe et al. applied this process onto Nylon-Cotton fabrics, impregnating them with diallyldimethylammonium chloride, and used pentaerythritoltetraacrylate with four vinyl groups as a cross-linker. pneumoniae and S.

However, the most direct and practical way to coat a material with a QAC coating is to use aerosol-assisted plasma deposition, described in Sec. In fact, to inject in the plasma a solution of quaternary ammonium salt with an atomizer is straightforward.

Salts of cetalkonium chloride, benzalkonium chloride, and cetylpyridinium chloride were dissolved at 2. The coating resisted washing at pH 2, 7, and 12, and microbial tests demonstrated that cetylpyridinium chloride and benzalkonium chloride-containing coatings provided significant protection against fungal contamination.

Schematic representation of the roll-to-roll APP reactor for the deposition of composite anti-bacterial coatings.

Interface Anal. Plasma-polymerized coatings can also be useful in building multi-layers, in some cases with an all-plasma processing method.

One can think to build a sandwich system in which anti-bacterial nanoparticles are trapped between two coatings having a regulatory role: the first layer acting as an adhesive interface with a substrate and the top layer having the role of controlling the release rate of the anti-bacterial agent.

Plasma processing offers the possibility to have three consecutive reactors each producing the bottom, the active, and the top layer respectively, exactly an all-plasma method. Just to give an example the bottom and top layers can be organic plasma deposited coatings; sandwiching Ag nanoclusters deposited by plasma sputtering.

However, more frequently the solution proposed for the active layer is a wet step, where the substrate coated with the bottom layer is placed in contact with a solution or suspension of anti-bacterial NPs or antibiotics. Vasilev et al. They demonstrated control over the silver release, by modulating the thickness of the overlayer Fig.

Furthermore, they showed that the coatings were compatible with osteoblast cells, which is important in medical device applications. Reproduced with permission from Vasilev et al. A similar multi-layer system has also been proposed by Alissawi et al.

They observed that the addition of the top layer can slow down the release rate in the water of silver ions. In the latter case, it can be supposed that water can interact with the top coating leading to the easier release of the silver. An interesting approach to multi-layer has been proposed by Kulaga et al.

The bottom one was obtained from low-pressure plasma polymerization of maleic anhydride and immersion in water for conversion in —COOH-rich coating. Then, the silver loaded sample was coated with a similar coating. The authors demonstrated that combining this coating with electron beam sterilization can lead to the formation of microcracks in the multi-layer without delamination that helps in regulating the release of the anti-bacterial agent.

Another approach uses GAS described earlier in Sec. III A 3 to load metal NPs into plasma polymer matrices. NPs can be deposited sequentially or simultaneously with the matrix; consequently, multi-layer sandwich structure or homogeneously mixed nanocomposite thin films can be produced.

The controlled ion release is achieved by tuning the number of embedded NPs and the thickness of the polymer capping layers. For example, bi-layered Cu NPs and thin films of PEO plasma polymers were produced [ Figs. aureus, MRSA and Pseudomonas aeruginosa P. aeruginosa , as shown in Fig. Bactericidal activity and cytocompatibility of Cu and Ag NP-loaded plasma polymers: a and b scheme and cross-sectional SEM of bi-layered Cu NPs embedded in PEO plasma polymer; c fluorescent microscopy images of alive green and dead red bacteria P.

Reproduced with permission from Nikitin et al. Copyright The Royal Society of Chemistry; d bactericidal activity against E. Reproduced with permission from Kratochvíl et al. Reproduced with permission from Vaidulych et al. KGaA; g and h bactericidal activity against E.

Reproduced with permission from Thukkaram et al. Interfaces 12 , Typically, a higher concentration of Cu or Ag NPs ensures a more decisive bactericidal action, as shown in the example of Cu NPs embedded in the fluorocarbon plasma polymer matrix, Fig.

However, one should keep in mind that biological tissue-contacting devices must meet the criterion of biocompatibility; that is, their performance should be harmless to cells.

Such a demand exerts greater restraint on the ion release kinetics, and a balance should be found between the bactericidal activity and the cytocompatibility.

coli and good cytocompatibility with MG63 and MC3T3 cells. This Tutorial aims to provide researchers with a comprehensive overview of plasma processing methods for engineering anti-bacterial surfaces. The focus of the Tutorial is made on backgrounds of plasma methods of surface treatment that are demonstrated with some typical examples of applications in the biomedical field.

The examples given in the Tutorial have revealed plasma's unique potential as a versatile tool for very effective control of the surface chemistry and surface morphology—the two key factors that determine the application area of novel materials.

The Tutorial gives an overview of the plasma-enabled processes for both low-pressure vacuum-based and atmospheric pressure conditions and the entire spectrum of common materials from metal alloys and ceramics to polymers and bio-scaffolds.

Impressive recent advances in plasma functionalization of surfaces suggest that plasma-assisted surface functionalization approaches are promising to produce anti-bacterial materials for targeted bactericidal applications ranging from medical tools and biomaterials to all kinds of surfaces used in everyday human life.

The plasma-modified surfaces have revealed the ability to actively control the interactions with bacteria, e. With this Tutorial, the authors aim to give a detailed and systematic description of different plasma methods and also provide rationality for a choice of the plasma methods depending on both requirements of bacterial killing mechanisms and properties of materials important in real-life applications.

The unique features of the plasma-assisted surface processing methods are emphasized in the Tutorial with a specific focus on anti-bacterial materials development.

The key plasma features are discussed in the Tutorial and physical manipulation of surfaces on atomic or nano-scale e. Importantly for practical applications, plasma technology of anti-bacterial surfaces engineering has several notable features.

Nonetheless, in some cases, the plasma-engineered antimicrobial surfaces may suffer from some disadvantages. Frequently encountered problems include the poor coating adhesion and stability in an aqueous media that may disable the biomaterials and the extensive use of nanoparticles that may cause a long-lasting toxicity impact on cells.

Therefore, comprehensive consideration of both advantages and disadvantages of plasma surface engineering should be at the center of designing nanocomposite and antimicrobial biomaterials with relevant plasma methods. The fast development of new plasma sources and our understanding of the mechanisms of plasma-surface interactions give the researchers a diversity of possible solutions in the field of anti-bacterial materials design and to solve future challenges in the field.

Among them, we can emphasize new trends in the development of a top-down approach where new plasma processing of anti-bacterial materials can be designed based on final requirements to the materials. Such an approach, different from the current paradigm of bottom-up experimental methodology, can be combined with plasma physics study and plasma-surface modeling and helps to save required time and costs for the development of new plasma methods of anti-bacterial materials engineering.

Second, the multifunctional anti-bacterial materials capable to combine different mechanisms of bacteria growth suppression are in high demand and can help to design the next generation of anti-bacterial surfaces but more systematic research is required.

In summary, plasma engineering of surfaces has several unique features allowing to manufacture a variety of anti-bacterial materials for almost all kinds of applications. The plasma-based methods of bactericidal surfaces engineering provide cost-effective, environmentally friendly, and scalable solutions for both research and industry with potential still to be fully discovered.

acknowledges the Vlaio project HBC. appreciates the support from the Czech Science Foundation via Grant No. GACR S. Sign In or Create an Account. Search Dropdown Menu. header search search input Search input auto suggest.

filter your search All Content AIP Publishing Portfolio Journal of Applied Physics. Advanced Search Citation Search. Sign In. Toggle Menu Menu Home Browse Collections Editor's Picks Featured Perspectives Press Releases Scilights Special Topics Tutorials Upcoming Special Topics Publish With Us Submit Your Manuscript Preparing Your Manuscript Publication Charges Author Resources AIP Author Services About Overview Editorial Board Editorial Advisory Board Journal Development Team Editorial Policies News Contact.

Skip Nav Destination Close navigation menu Article navigation. Volume , Issue 1. Previous Article Next Article. Contact-killing surfaces.

Antifouling surfaces. Drug-release surfaces. Surface nano-patterning methods. Functional grafting and plasma polymerization. Conflict of Interest. Author Contributions.

Article Navigation. Research Article January 03 Plasma technology in antimicrobial surface engineering Anton Nikiforov Anton Nikiforov a. nikiforov ugent. This Site. Google Scholar. Chuanlong Ma Chuanlong Ma. Andrei Choukourov Andrei Choukourov. Fabio Palumbo Fabio Palumbo.

The following are some of the key promises for the significant growth of antimicrobial coatings in recent years:. For the manufacturers of cleaning solutions and disinfectants, the growth of antimicrobial coating products may be a cause for concern.

After all, a lot of money, time, and research have been poured into developing traditional and environmentally certified cleaning products to help stop the spread of disease and keep people in all types of facilities healthy. However, these manufacturers, along with the entire professional cleaning industry, have not yet heard the entire story.

The U. Because of this and concerns about the substances used in antimicrobial products, some health care organizations are having second thoughts about the use of these coatings.

In fact, Kaiser Permanente, which operates 38 hospitals and more than medical offices in the United States, has recently stopped using these products in its facilities. However this eventually plays out, the most important issue has already been raised: the true effectiveness of these coatings.

While lead improved the performance of paint, when the paint naturally deteriorated, it resulted in increased exposure to lead, which accumulates in the bodies of young children. Additionally, due to the widespread use of lead paint, the cost of remediation has been staggering as we have struggled to eliminate it since What we know for certain is that using proper cleaning solutions and cleaning methods is still the best way to stop the spread of disease and keep people healthy in all types of facilities.

Stephen P. Ashkin is president of The Ashkin Group, a consulting firm specializing in green cleaning and sustainability. He can be reached at [email protected]. Pros and Cons of Antimicrobial Surface Coatings Identifying the true effectiveness of coatings.

by Stephen P. Uses for Antimicrobial Coatings Antimicrobial coatings are typically applied to counters, walls, door handles, and other high-touch areas; HVAC vents and mechanicals; and many other surfaces.

The following are some of the key promises for the significant growth of antimicrobial coatings in recent years: They help stop the spread of pathogens that can cause disease, which is especially important in a hospital setting where many people already have weakened immune systems.

They have the potential to meaningfully lower the environmental impact of cleaning in a medical setting, where scores of different chemicals are used for a variety of purposes.

If surfaces do not need as thorough a cleaning to prevent the spread of disease, it could reduce the amount of cleaning time—and therefore, cost—necessary to maintain facilities.

The Flip Side The U. Updated May 15, from an article originally posted January 29, Posted On January 29, Ashkin President, The Ashkin Group Stephen P. Topics Tags.

Also in Infection Control. January 31, Kathleen Misovic. Think Before You Disinfect. January 29, Dr.

Anton NikiforovChuanlong MaImproved lipid breakdown ChoukourovFabio Palumbo; Plasma technology in antimicrobial surface engineering. Anti-microhial design xurface advanced materials with superb anti-bacterial efficiency by engineering appropriate surfface properties has now become Anti-microbial surface treatments consolidated Anti-microbial surface treatments Body composition measurement improve the functional properties treat,ents Anti-microbial surface treatments, metals, and a variety of Intestinal nutrient absorption materials. Antimicrobial coatings Anti-microbial surface treatments create a healthier living and working environment and Anti-microbia, holistic solutions to people treatmeents health problems. This Tutorial will serve as a reference point for scientists pursuing sustainable antimicrobial coatings development, by providing a design framework and a toolbox for enabling plasma-based technologies in additive engineering of new materials. A succinct description of how novel, efficient methods based on non-equilibrium reactive plasma chemistries can be applied to produce sophisticated, high-value advanced coatings with the anti-bacterial or antifungal function will be used to illustrate the utility of plasma methods. Described plasma-based methods can minimize the process steps and dramatically reduce the use of expensive and hazardous reagents, which is a point of high interest in the development of novel sustainable and green manufacturing processes. The Tutorial aims to provide an overview of the principle and state-of-the-art in plasma technology, which is useful for researchers and broad auditoria of students working in antimicrobial materials development and additive engineering.

ich beglückwünsche, dieser sehr gute Gedanke fällt gerade übrigens