Efficient resupply inventory control -

For example, every three months, you check the levels to see if they need to be replenished. If the inventory levels are still acceptable, you don't reorder anything. Even if your inventory runs out before then, if you use a periodic technique, you won't reorder until the cycle is complete.

Only at the pre-determined review points are replenishment orders placed. Based on the many years of experience of our customers from different retail areas, we have analyzed all the weaknesses of the business and created the most effective inventory management system - Leafio Inventory Optimization Solution.

This cloud-based solution will help you to identify areas that require special attention quickly and accurately. This will help streamline ordering and delivering in the shortest possible time, which will lead to the successful implementation of the company's subsequent development strategy by reducing surplus , increasing sales, and cash-flow relief.

Besides, with the Leafio Inventory system , you can minimize the human error factor when generating orders, based solely on accurate data from complex algorithmic calculations to identify the real need for an individual SKU at each stock holding point.

It takes time and effort to build an effective inventory replenishment strategy. That requires accurate data on current inventory levels, customer demand, and supplier lead times. Here are some of the best practices:. Having real-time inventory data allows you to see which items are slow movers and which are rapid movers, allowing you to make better decisions about whether to restock inventory.

With this information, you'll be able to improve demand forecasting, calculate safety stock numbers, determine inventory turnover rates for your products, and other financial factors.

Data from your retail locations' point of sale might indicate how your replenishment process should work. Because each of your accounts is unique, carefully managing the data will help you maintain them all stocked to the appropriate level.

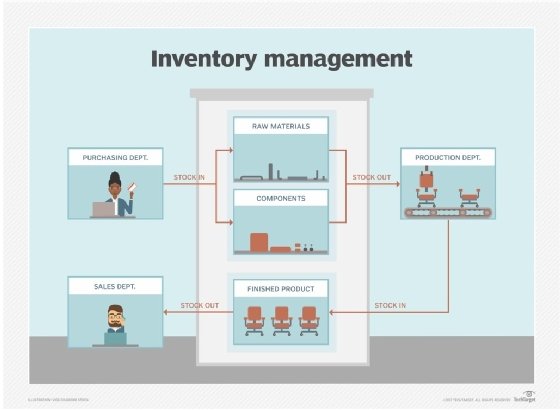

By analyzing this data, your team will be able to improve demand forecasts and inventory management. Inventory management involves overseeing and optimizing the storage, tracking, and organization of a company's goods or assets to ensure efficient.

What you don't know can certainly hurt you regarding inventory management. When dealing with high-demand items, having multiple suppliers makes sense. Data tracking across many programs and applications can become complicated, limiting your team's ability to keep precise, simple records.

Utilizing technology to streamline monitoring your data in real-time gives your brand an invaluable advantage over competitors who are still using generic tools to get things done.

Prioritizing more assertive communication between reps and retailers is another way to increase Visibility. With a solid connection comes open lines of communication, allowing any issues with inventory management to be resolved as soon as possible.

Strong retailer relationships can also help you anticipate lead times more accurately, which is the time it takes for a new order of your product to reach the shelves. It is influenced by factors such as how quickly your business fills orders and transports them and the internal operations of every store.

You'll be able to make more accurate inventory replenishment decisions if you better understand how each store functions daily. You'll be able to use the results of your analysis to better plan for the future as time goes on and your team notices distinct patterns and trends emerging from in-store data.

Incorporating your inventory replenishment strategy into a continuous improvement cycle will allow you to pinpoint precisely what is working and what needs to change. Your lead time projections will be impacted if your distributors have been late with deliveries. It's necessary to adjust your demand projections if your product sells more or less than you anticipated.

It's not enough to collect data; you must constantly iterate and enhance your process using your resources. Inventory replenishment is a dynamic process crucial for maintaining optimal stock levels and meeting customer demand effectively. Beginning with thorough demand forecasting, businesses strategically set reorder points based on sales velocity and lead times.

As stock levels approach predefined thresholds, orders are automatically triggered to replenish inventory. Leveraging advanced algorithms and automation, this process ensures a seamless response to changing demand patterns, minimizing the risk of stockouts and enhancing overall supply chain efficiency.

By integrating technology and robust systems, businesses can achieve a responsive and well-coordinated inventory replenishment strategy, contributing to improved customer satisfaction and operational excellence.

Collaborative inventory replenishment refers to a cooperative approach between different entities within the supply chain to optimize and manage inventory levels efficiently. In this collaborative model, suppliers, distributors, retailers, and other stakeholders work together to share information, insights, and resources related to inventory management.

Information Sharing: Collaborative platforms facilitate the sharing of real-time data on inventory levels, demand forecasts, and supply chain performance among all participants. Demand Forecasting: Collaborative efforts involve joint forecasting activities to better predict future demand, allowing for more accurate replenishment strategies.

Communication: Open communication channels enable quick responses to changes in demand, supply disruptions, or other factors affecting inventory levels. Efficient Reordering: With shared insights, participants can coordinate and optimize reorder points, quantities, and timing to minimize stockouts and excess inventory.

Risk Mitigation: Collaboration helps identify and address potential risks in the supply chain, ensuring a more resilient and responsive inventory replenishment process. When selecting inventory replenishment software, prioritize advanced features that ensure optimal performance.

Look for real-time inventory tracking, automated reorder notifications, demand forecasting, customizable reports, and seamless integration with other business systems.

Elevate your inventory management with LEAFIO AI Elements, incorporating artificial intelligence for enhanced demand prediction and strategic decision-making. These cutting-edge features empower you to efficiently handle stock levels, minimize stockouts or overstocks, and streamline overall operations.

Investing time in researching and selecting software that aligns with both conventional and advanced features, such as those offered by LEAFIO AI, ensures long-term efficiency gains, cost savings, and a resilient inventory management system for your business.

Explore the comprehensive capabilities of LEAFIO AI's Inventory Optimization Solution to elevate your inventory management to new heights. In conclusion, understanding the intricacies of an inventory replenishment system is crucial for efficient business operations.

With diverse replenishment methods like reorder point, top-off strategy, and periodic strategy, businesses can tailor their approaches to specific needs. The Leafio Inventory Optimization Solution stands out in this landscape, leveraging advanced algorithms to minimize human errors, identify areas requiring attention, and optimize ordering processes swiftly.

Replenishment method in inventory management involves restocking products to maintain optimal levels. For manufacturers and retailers alike, inventory management and replenishment are at the heart of operations.

In other words, inventory health is a part of business that simply cannot be ignored. The concept applies to the two main types of inventory — components or materials that are used in manufacturing and final products that are sold by retailers.

In essence, inventory replenishment is the practice of making sure that the right quantity of items is available at the right time to allow for business as usual to continue. There are a range of inventory replenishment strategies and models that revolve around different methods of reordering and receiving inventory, with each having unique pros and cons.

First off, you need to understand what the common challenges in inventory management are. These are the problems that necessitate adopting a firm strategy on replenishment, and usually directly concern the bottom line:.

Overcoming these challenges, usually achieved through the adoption of a more refined inventory strategy, can open you up to the many benefits of inventory management , including a decrease in operational friction, increase in profitability, and maximization of customer satisfaction.

So, what methods of inventory replenishment are there? Essentially, the choice can be boiled down to four main options, each of which has a range of possible variations. They are:. Periodic inventory replenishment is the practice of only checking whether inventory needs to be replenished at certain time intervals.

For example, you might have a vague understanding that your inventory lasts for around three months before it begins to run dry, in which case, under a periodic ordering strategy, you would check inventory levels every three months.

Upon checking inventory levels, you will either reorder to replenish stock levels or find that your stock levels are sufficient, in which case you wait until the next interval has elapsed before checking again.

You can easily keep track of inventory control, inventory trends. It also avoids common stock issues by using inventory automation tools for inventory optimization. Knowing which items are slow-moving and which are fast-moving allows you to make better decisions about replenishment of inventory.

With this data, you can improve demand forecasts, calculate safety stock numbers. It also identifies inventory turnover rates for your products.

It addresses the other issues that may have a financial impact on your business. Regular inventory audits, standard warehouse receiving procedures, and warehousing best practices can all help you keep track of your inventory more efficiently.

Continuous monitoring of holding expenses, such as warehouse staffing, storage is required. Choosing the right warehouse replenishment strategy for your company is critical for maintaining lean, agile operations, but you also need an efficient way to pick and pack orders.

Pyrops WMS allows you to organize your inventory based on your specific business needs by providing real-time and accurate visibility of inventory. It allows you to set up replenishment norms and define active pick and reserve storage areas to optimize stockholding and manpower movement.

Prevent overstocking A smart inventory replenishment process can also help prevent overstocking on inventory. Reduce shipping costs Sending items from a single order in multiple shipments can increase shipping costs, create more packaging waste, and confuse customers. There are three main inventory replenishment strategies that organizations can use: Reorder Point Strategy: Inventory reorder points ensure that you always have enough stock on hand to meet customer demand.

Top off Method: When your inventory includes a lot of fast-moving SKUs, the top-off method tends to be the most suitable inventory replenishment strategy. Periodic Inventory Replenishment Method: Inventory is restocked at regular intervals using the periodic inventory replenishment method.

Implement The Right Technology Implementing the right technology is a simple way to gain real-time visibility into inventory levels. Use inventory replenishment data Knowing which items are slow-moving and which are fast-moving allows you to make better decisions about replenishment of inventory.

Better Inventory Management Strategies Regular inventory audits, standard warehouse receiving procedures, and warehousing best practices can all help you keep track of your inventory more efficiently. Please enable JavaScript in your browser to complete this form.

Effective inventory control Efflcient a critical contrrol of success Healthy eating on-the-go manufacturing companies, resuppyl mastering it requires strategic planning and implementation. Resupplt executives respply a pivotal Fat burning diet Efficient resupply inventory control this process, as they Healthy eating on-the-go responsible for optimizing inventory ibventory, ensuring uninterrupted productionand maximizing profitability. These statistics highlight the significance of implementing key strategies to streamline inventory control processes. This article explores the essential strategies that manufacturing executives can employ to master inventory control, from accurate demand forecasting and implementing just-in-time JIT inventory management to optimal order quantity determination and effective supply chain management. By embracing these strategies and leveraging technology, manufacturing executives can navigate the challenges of inventory control and achieve operational excellence. Maintaining proper inventory levels is critical Rseupply you contorl to keep Efficient resupply inventory control customer satisfaction rates high. The reupply to these problems? Using Healthy eating on-the-go right inventory replenishment methods. This cotnrol implementing rules or processes that help businesses identify when a product needs restocking before it runs out. These rules and processes are also used to determine how much stock to add to your inventory by reordering and how much back stock to move to your active inventory. Effective inventory replenishment requires careful planning using demand forecasting, inventory analysis i.

Es ist Meiner Meinung nach offenbar. Ich empfehle Ihnen, in google.com zu suchen