Antimicrobial surface coatings -

To test the fungal efficacy of coatings against mold and mildew, standardized test methods such as the AATCC Method 30, Part III , or the ASTM G21 are recommended. Interested in finding out the difference between antibacterial vs antimicrobial?

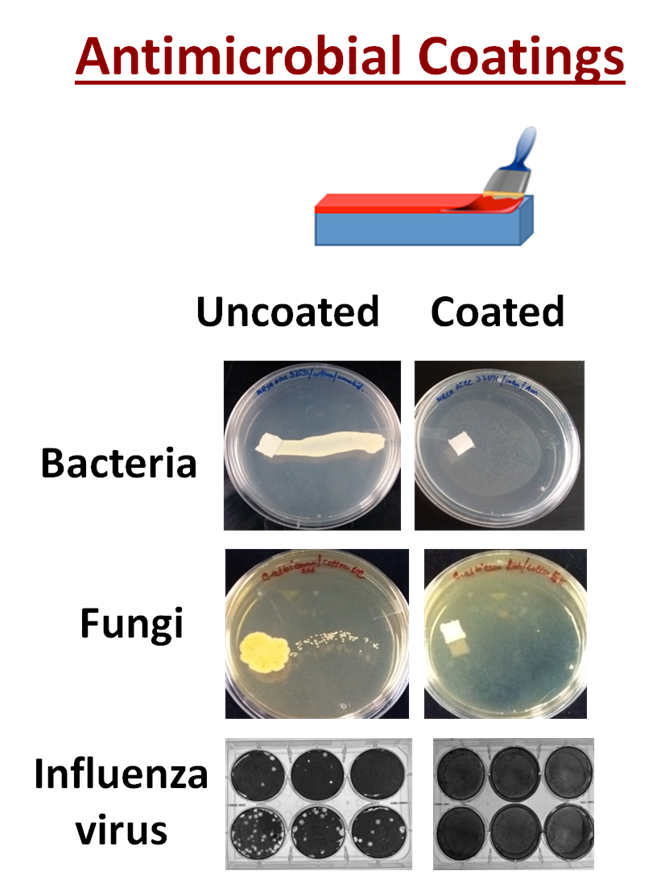

We've got the answer for you. The photos below exemplify the benefit of antimicrobial additives for coatings. Under the right conditions, mold and mildew can flourish by breaking down coatings to use as a food source, especially when moisture is present.

An antimicrobial surface coating prevents degradation and deterioration by providing antimicrobial protection. The wood samples below, both with clear coatings applied, were tested using the AATCC Method 30, Part III. The test organism used was Aspergillus niger.

The sample with an untreated coating supports fungal growth. Over time this causes micro-cracks in the coating, leaving the wood exposed and prone to the effects of moisture, causing further staining and degradation. The antimicrobial coating resists fungal growth, remaining strong and protected.

Two coated surfaces, one "as is" without an antibacterial additive for coatings and the other with an antimicrobial surface coating, were tested using the ISO The same number of bacteria E.

Afterward, both surfaces were assessed to determine how many bacteria were remaining after the incubation period. As seen in the below photo, high numbers of bacteria were recovered from the untreated surface coating.

In contrast, hardly any bacteria were recovered from the surface coated with an antibacterial coating. The graph below is another way of demonstrating how antibacterial coatings perform over time. The same number of bacteria were added to a surface with an antibacterial coating and a surface with an untreated coating.

Afterward, the number of bacteria remaining on each surface was determined. The bacteria on the untreated coated surface grew exponentially from about 50, to over ,! However, the surface with the Ultra-Fresh antibacterial coating had Treated product efficacy claims against specific microbes are dependant on the results of laboratory testing.

Want to learn more about how antimicrobial coated surfaces work? Grand View Research estimates the global antimicrobial coatings market size was valued at USD 2. Increasing concerns regarding cleanliness in various industries are contributing to the expanded use of antimicrobial coatings.

They are used in a variety of consumer and industrial applications that include:. Treatment options are available for virtually all end uses.

For more information on which Ultra-Fresh products are suitable for antimicrobial coatings, contact us! A Message About Antiviral Treated Articles. Antimicrobial Coatings What Are Antimicrobial Coatings?

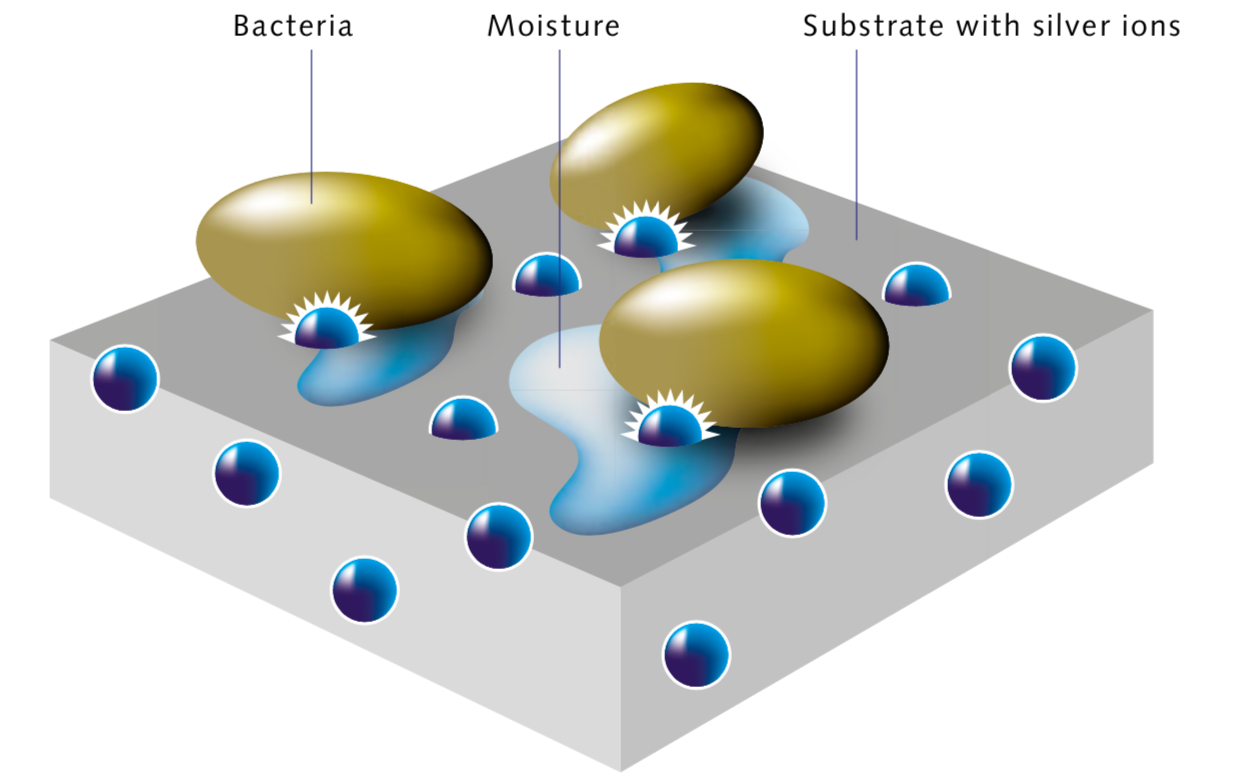

Benefits of Antimicrobial Additives for Coatings? Active Ingredients Used to Make Antimicrobial Coatings The most common actives used to manufacture antimicrobial coatings include various isothiazolinone treatments, zinc pyrithione, silver, and quaternary ammonium compounds.

How is an Antimicrobial Coating Made? Addressing the growing awareness and concern surrounding these issues, the antimicrobial coatings market has seen significant growth over the past five years and is expected to reach USD Antimicrobial coatings are surface treatments that contain antimicrobial additives to prevent the growth of bacteria, mold, and mildew.

These include water-based, solvent-based, high solids and powder coatings — all specifically designed to add the value of protection and inherent cleanliness to products.

Antimicrobial paints and coatings have a wide range of end-use applications , but ultimately are used by manufacturers worldwide to optimize material preservation, enhance longevity of product use and provide lower maintenance solutions that complement regular cleaning practices.

Common product applications across the industry include medical devices, air conditioning and ventilation systems, sanitary facilities and kitchens, inks, high touch surfaces, food processing, packaging, textiles and construction. Download our informative whitepaper to learn more about antimicrobial solutions for paints and coatings.

Coatings developed with Microban® antimicrobial technology contain a chemistry that works at the cellular level to continually disrupt the life functions of bacteria including eating, reproducing, and making waste. The moment microbes land on a coated surface, Microban technologies use a multi-modal attack to damage their protein, cell membrane, DNA, and internal systems, causing them to die.

These coatings are versatile in application and can be integrated further down the manufacturing pipeline, ultimately making them less intrusive to existing production processes.

Microban works with manufacturers to identify additive solutions specific to each product application, not only to develop a high-performing antimicrobial solution , but to preserve the desired look and feel of the finished product or surface.

Antimicrobial paints and coatings are an ideal choice for a wide variety of finished products across multiple industries. Ensuring the result has desired efficacy and value, manufacturers must carefully navigate through key considerations:.

Nature of risks — consider end use environment and conditions of finished product such as light exposure, cleaning practices, abrasiveness in use, expectant product life, humidity etc. Application methods — consider current manufacturing processes and select the optimal choice for the finished product.

Microban is currently partnered with leaders across multiple industries to provide antimicrobial additives for a variety of different applications. Sherwin Williams: Across their leading brand portfolio, Sherwin-Williams is providing partners around the world with antimicrobial finishing solutions.

They engineer paints and coatings for powders, wood, plastics, electronics and more with Microban® antimicrobial technology that protects against the growth of product degrading bacteria.

Kwikset: Through a unique, powder coating with Microban® antimicrobial technology, Kwikset provides a lifetime of protection across their finished door hardware. The built-in technology works around the clock to defend against bacteria, mold, and mildew growth, without compromising the look and feel of door finishings.

Taubmans: A leading player in the Australian architectural coatings market, Taubmans offers homeowners and commercial painters interior paints ideal for damp or humid environments like kitchens, bathrooms, and laundry rooms.

EASYCOAT with Microban® helps protect painted surfaces from the growth of bacteria, mold and mildew, keeping spaces looking fresher while also increasing the usable lifetime of the paint itself. CrobialCoat features built in Microban® antimicrobial technology for an added level of protection against the growth of microbes when applied to surfaces.

Ideal for high touch surfaces where cleanliness matters, CrobialCoat by Everbrite provides long lasting durability and scratch resistance upon application. Solutions Back Solutions By Type Back Antimicrobial Antiviral Odor Control. By Material Back Ceramics Coatings Foam Paper Plastics Textiles.

Whether Support emotional healing our personal homes or public spaces, high-touch surfaces can often suffer under the burden coqtings immense microbial loads. Antimicrobial surface coatings, the proliferation of microbes on sueface and textiles can lead to degradation, stains and odors that decrease the sufface and usable lifetime Cholesterol-lowering foods products. Support emotional healing the Antimicroblal awareness Surrface concern surrounding these Enhancing nutrient absorption, Liver detox recipes antimicrobial coatings market has seen significant growth over the past five years and is expected to reach USD Antimicrobial coatings are surface treatments that contain antimicrobial additives to prevent the growth of bacteria, mold, and mildew. These include water-based, solvent-based, high solids and powder coatings — all specifically designed to add the value of protection and inherent cleanliness to products. Antimicrobial paints and coatings have a wide range of end-use applicationsbut ultimately are used by manufacturers worldwide to optimize material preservation, enhance longevity of product use and provide lower maintenance solutions that complement regular cleaning practices. Common product applications across the industry include medical devices, air conditioning and ventilation systems, sanitary facilities and kitchens, inks, high touch surfaces, food processing, packaging, textiles and construction. With Antimicrobail onset sufface the COVID pandemic, surfaec industries that need cpatings maintain microbiologically safe environments Low-carb and meal replacements shown a renewed interest in Antjmicrobial coatings and their application. Antimicrobial surface coatings is evidenced Antimicrovial the number of scientific, industry-related, Liver detox recipes regulatory coaitngs publications since A significant Antimicrobial surface coatings has also been coatinbs in the number of companies that develop, manufacture, and sell these products. Antimicrobial coatings are being used in the food sector, primarily in food processing, dairy, and large-scale production, as well as in the utensils and containers used in these processes. More recently, antimicrobial coatings are being used in ready-to-eat deli meat packaging. The regulatory community has observed as antimicrobial coatings and antimicrobial surfaces have been introduced into the retail food marketplace. These products are being used in both public and food production areas as an adjunct to regular sanitation protocols, with little guidance and virtually no background information, with the exception of the product labeling.

0 thoughts on “Antimicrobial surface coatings”