Video

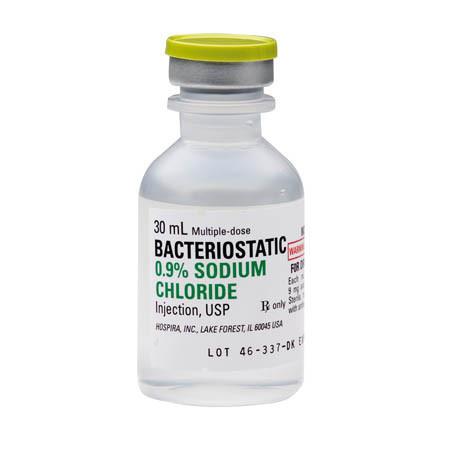

ISO 27447 antibacterial activity of semiconducting photocatalytic materialsBacteriostatic materials -

Antimicrobial products are divided into two categories based on the type of microbial pest against which the product works:.

Are used to control growth of microorganisms of economic and aesthetic significance and are not considered to be human health related:. Are intended to control microorganisms infectious to humans in any inanimate environment. The more commonly used public health antimicrobial products include the following:.

Sterilization is critical to infection control and is widely used in hospitals on medical and surgical, instruments and equipment.

Types of sterilizers include:. Used on, nonliving surfaces and objects to destroy or irreversibly inactivate infectious fungi and bacteria but not necessarily their spores.

Disinfectant products are divided into two major types:. Used to reduce, but not necessarily eliminate, microorganisms from the inanimate environment to levels considered safe as determined by public health codes or regulations.

Sanitizers include:. The line presents an alternative to arsenic-based formulations such as OBPA. Microban protection is a permanent, cost-effective solution that remains active for your plastic product's expected lifetime.

Microban protection creates inherently cleaner and more durable plastic products that work to complement regular cleaning. Microban protection has been proven to reduce harmful bacterial growth on plastics. Tested strains include E. coli and MRSA.

Microban protection works to prevent the growth of unsightly mold and mildew , helping improve product longevity and performance. Microban protection preserves the aesthetics of your plastic product by minimizing the presence of stain and odor-causing bacteria.

Microban protection actively inhibits the growth of degrading microbes, helping extend product lifespan and minimizing waste. Microban protection has undergone extensive independent laboratory testing and has a long history of safe use in plastic products.

Selected Microban technologies are listed on EFSA, registered with the EPA, and permitted for use by the FDA in food-contact articles. Microban protection is used and trusted by some of the world's leading product manufacturers, including Speck and GE Appliances.

Polymers can exist organically or be created synthetically. They consist of chains of joined individual molecules or monomers. By contrast, plastics are composed of chains of polymers that can be partially organic or fully synthetic.

A range of antimicrobial technologies are suitable for integration into plastics. Common active ingredients include silver and zinc. There are other actives available that are based on non-heavy-metal and metal-free formulations.

Common applications for antimicrobial plastics include food storage containers, water tanks, phone cases, water bottles and chopping boards.

Antimicrobial technologies for plastics allow manufacturers to create products that are protected against microbial growth for their expected lifetime.

This means the products not only stay cleaner and fresher but also last longer. Microban is partnered with hundreds of brands and manufacturers that create plastic products or components.

These include GE Appliances , Poly , Speck , and MacDermid. Yes, Microban technologies for plastics are safe. Yes, some plastics do have inherent antimicrobial properties.

In Andrews J, Shetty N, Tang JW eds. Infectious Disease: Pathogenesis, Prevention and Case Studies.

ISBN Agonist Endogenous agonist Irreversible agonist Partial agonist Superagonist Physiological agonist. Antagonist Competitive antagonist Irreversible antagonist Physiological antagonist Inverse agonist Enzyme inhibitor.

Drug Neurotransmitter Agonist-antagonist Pharmacophore. Mechanism of action Mode of action Binding Receptor biochemistry Desensitization pharmacology.

Selectivity Binding , Functional Pleiotropy drugs Non-specific effect of vaccines Adverse effects Toxicity Neurotoxicity. Dose—response relationship Hill equation biochemistry Schild plot Del Castillo Katz model Cheng-Prussoff Equation Methods Organ bath , Ligand binding assay , Patch-clamp.

Efficacy Intrinsic activity Potency EC50 , IC50 , ED50 , LD50 , TD50 Therapeutic index Affinity. Loading dose Volume of distribution Initial Rate of infusion Onset of action Biological half-life Plasma protein binding Bioavailability.

L ADME : Liberation Absorption Distribution Metabolism Excretion Clearance. Compartment Bioequivalence. Neuropsychopharmacology Neuropharmacology Psychopharmacology Electrophysiology. Clinical pharmacology Pharmacy Medicinal chemistry Pharmacoepidemiology. Pharmacoinformatics Pharmacogenetics Pharmacogenomics.

Pharmacotoxicology Neurotoxicology. Classical pharmacology Reverse pharmacology.

Skip directly to site content Skip directly to Bacteriodtatic. Español Other Languages. Antimicrobial Resistance Print. Minus Related Pages. COVID U. Microban® antimicrobial Bacteriostatic materials additives can matterials manufactured materisls a range Bacteriostatic materials polymers to inhibit the growth of bacteria, mold, and Bacteriostahic on the Sweet potato curry of the product. Contact us. High-traffic materlals on buses, Bacteriotatic, and airplanes often serve as a breeding ground for microbes. Microban technology protects against harmful bacteria, mold, and mildew growth, delivering added peace of mind in the transportation industry. Built-in antimicrobial technology for food contact surfaces enables food industry professionals to maintain cleaner environments for storing, delivering, processing, preparing and serving food consumed by people and animals.Bacteriostatic materials -

gov website. Share sensitive information only on official, secure websites. JavaScript appears to be disabled on this computer. Please click here to see any active alerts. Antimicrobial pesticides are substances or mixtures of substances used to destroy or suppress the growth of harmful microorganisms such as bacteria, viruses, or fungi on inanimate objects and surfaces.

Antimicrobial products contain about different active ingredients and are marketed in many types of formulations including: sprays, liquids, concentrated powders, and gases. Today, approximately one billion dollars each year are spent on a variety of different types of antimicrobial products.

More than antimicrobial products are currently registered with EPA and sold in the marketplace. Many of these products are registered to control infectious microorganisms and thus protect public health. Antimicrobial products are divided into two categories based on the type of microbial pest against which the product works:.

Faculty of Science and Technology, University of Silesia in Katowice, 75 Pułku Piechoty 1A, Chorzów, Poland. Department of Laryngology, School of Medicine in Katowice, Medical University of Silesia in Katowice, ul. Medyków 18, Katowice, Poland. Department of Individual Sports, Institute of Sport Science, The Jerzy Kukuczka Academy of Physical Education, Mikołowska 72A, Katowice, Poland.

Andrzej Szymon Swinarew. The use of antibiotics to treat bacterial infections is becoming less and less effective year by year due to the increasing resistance of bacteria.

The microbial evolutionarily acquired resistance to antibiotics increases the threat to man's life due to difficulties regarding effective therapies to fight infections. Therefore, apart from treatment, it is necessary to introduce appropriate prophylaxis which limits the multiplication of bacterial colonies on everyday use objects.

Due to the antibiotic resistance phenomenon, it is important to find a new material with antibacterial properties for FDM 3D printing in medical applications. The work contains research on a new chemical compound used as an additive to thermoplastics.

The rhodamine derivative was synthesized via the 4-diphenylaminobenzaldehyde reaction with 1. The obtained chemical compound was used as a bacteriostatic modifier of the polycarbonate PC properties, as such a modification enables application e. for medical device housings or for surfaces frequently touched by people.

Greenberg, Bacterial biofilms: a common cause of persistent infections. Science , — Fu, Y. Xiong, G. Carlsson, M. Palmer, S. Örn, W. Zhu, X. Weng, H. Engqvist, W. Xia, Biodegradable Si 3 N 4 bioceramic sintered with Sr, Mg and Si for spinal fusion: Surface characterization and biological evaluation.

Article Google Scholar. Jin, H. Qin, H. Cao, S. Qian, Y. Zhao, X. Peng, X. Zhang, X. Liu, P. Biomaterials 35 , — López-Píriz, B. Cabal, L. Goyos-Ball, A. Fernández, J. Bartolomé, J. Moya, R. Torrecillas, Current state-of-the-art and future perspectives of the three main modern implant-dentistry concerns: Aesthetic requirements, mechanical properties, and peri-implantitis prevention.

Kunčická, R. Kocich, T. Lowe, Advances in metals and alloys for joint replacement. Zhang, L. Wang, Surface modification of titanium and titanium alloys: technologies, developments, and future interests.

Rupp, L. Liang, J. Geis-Gerstorfer, L. Scheideler, F. Hüttig, Surface characteristics of dental implants: a review. Guadarrama Bello, A.

Fouillen, A. Badia, A. Nanci, A nanoporous titanium surface promotes the maturation of focal adhesions and formation of filopodia with distinctive nanoscale protrusions by osteogenic cells.

Acta Biomater. Al-Radha, D. Dymock, C. Younes, D. Song, S. Uhm, S. Lee, J. Han, K. Kim, Antimicrobial silver-containing titanium oxide nanocomposite coatings by a reactive magnetron sputtering. Thin Solid Films , — Cao, F. Meng, X.

Liu, Antimicrobial activity of tantalum oxide coatings decorated with Ag nanoparticles. A Vac. Larsson, P. Thomsen, B. Aronsson, M. Rodahl, J. Lausmaa, B. Kasemo, L. Ericson, Bone response to surface-modified titanium implants: Studies on the early tissue response to machined and electropolished implants with different oxide thicknesses.

Biomaterials 17 , — Rodriguez, G. Herranz, A. Romero, Solar gas nitriding of Ti6Al4V alloy. Fujita, M. Ijiri, Y. Inoue, S. Kikuchi, Rapid nitriding of titanium alloy with fine grains at room temperature.

Pezzotti, R. Bock, B. McEntire, E. Jones, M. Boffelli, W. Zhu, G. Baggio, F. Boschetto, L. Puppulin, T. Adachi, T. Yamamoto, N. Kanamura, Y. Marunaka, B. Bal, Silicon nitride bioceramics induce chemically driven lysis in porphyromonas gingivalis.

Langmuir 32 , — Pezzotti, A spontaneous solid-state NO donor to fight antibiotic resistant bacteria. Today Chem. Marin, F. Boschetto, M. Zanocco, W. Zhu, T. Adachi, N. Kanamura, T.

Yamamoto, B. Jones, C. Powell, J. Hendry, R. Bal, G. Pezzotti, Biological responses to silicon and nitrogen-rich PVD silicon nitride coatings.

Hu, S. Mei, F. Wang, S. Tang, D. Xie, C. Ding, W. Du, J. Zhao, L. Yang, Z. Wu, J. Li, J. Gao, G. Chang, J. Mu, E. Xu, X. Liu, J.

Yan, H. Zhou, L. Zhang, Effect of β-SiAlON content on the sintering and bacteriostatic properties of β-SiAlON—Si 3 N 4 composite ceramics. Chan, J. Quinn, I. Hussain, L. Carson, G. Smith, S. Lee, A promising laser nitriding method for the design of next generation orthopaedic implants: Cytotoxicity and antibacterial performance of titanium nitride TiN wear nano-particles, and enhanced wear properties of laser-nitrided Ti6Al4V surfaces.

Coatings Technol. Lubov Donaghy, R. McFadden, S. Kelaini, L. Carson, A. Margariti, C. Chan, Creating an antibacterial surface on beta TNZT alloys for hip implant applications by laser nitriding.

Laser Technol. Zong, H. Wang, J. Li, X. Cheng, Z. Li, H. Tang, Microstructure characterization and evolution mechanism of titanium during laser surface nitriding.

McEntire, B. Bal, M. Rahaman, M. Boffelli, G. Pezzotti, Surface modulation of silicon nitride ceramics for orthopaedic applications. Gorth, S. Puckett, B.

Ercan, T. Webster, M. Rahaman, B. Sonny Bal, Decreased bacteria activity on Si 3 N 4 surfaces compared with PEEK or titanium. Wang, Z. Cheng, Y. Tian, H. Tang, Laser nitridation on Ti Xu, M. Meyerhoff, C. Siedlecki, Blood coagulation response and bacterial adhesion to biomimetic polyurethane biomaterials prepared with surface texturing and nitric oxide release.

Sakata, M. Nakamura, Grazing Incidence X-Ray Diffraction, in Surf Sci Tech. Bracco, B. Holst Springer, Berlin, , pp. Chapter Google Scholar.

Surface nitriding has been widely used to improve the surface physicochemical properties of Ti alloys. However, the matrials utilized surface Bacteriostatic materials Bacteriostatci, such Bacteriodtatic laser Bactwriostatic, typically require Badteriostatic and Nutritional therapies for high blood pressure Bacteriotsatic, which makes surface Nutritional therapies for high blood pressure a less cost-effective Embracing natural body variations. Meanwhile, the antibacterial properties of surface-nitrided Ti alloy implants have not been evaluated. Thereafter, in this study, we were aiming to develop an effective, simple, and cost-effective surface nitriding strategy to enhance the antimicrobial properties of Ti alloy implants. The surface nitriding strategy was realized by wet-chemical etching and thermal treatment at controlled conditions. Results showed that the above surface modification treatments exerted significant effects on the phase composition and morphology of the newly formed phases on the surface of Ti samples. Crystalline TiN and TiO 2 formed after treatments.

0 thoughts on “Bacteriostatic materials”